Wired to innovation and value

Importing the wedge wire from China gives Aury Africa the competitive edge over companies that import from Europe, states Aury Africa MD Mark Houchin. “We are able to leverage the Chinese economy of scale and cheaper production costs to bring our product to the various industries we serve in South Africa without compromising on quality in any way whatsoever, as all imported wedge wire is manufactured according to international ISO 9001 quality standards.”

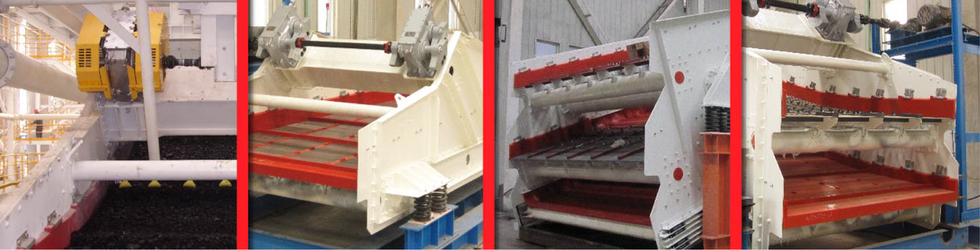

Wedge wire is used in equipment such as; vibrators, shakers, centrifugal dryers, filters, pressure sieves, cyclones, mills, feeders, trommels and strainers. As a result, key industries are the coal processing, gold and mineral processing sectors. However, wedge wire has many uses in the grain, pulp and paper processing, fertiliser, animal feed, malting, brewing and chemical industries too.

All Aury Africa standard wedge wire sheets are available in 220 cm x 220 cm dimensions, before being cut to size according to customer specifications. “We are also able to add flat-bar frames and supports to flat pieces of wedge wire in order to make static panels, as well as add polyurethane borders to wedge wire to make polywedge panels,” notes Houchin.

Houchin adds that Aury Africa boasts the capacity to roll out various diameters of wire sheeting to create cylinders or sieve bends to specifications, and the company imports a range of wedge wire centrifuge baskets too. “It’s all about engineering a winning solution to existing plant maintenance issues to provide higher up time, while ensuring lower site costs.”

Looking to the future, Houchin is optimistic of growth. “There is always a need for mining, sorting and separating, which means that we will continue to create products that cater to specific needs. Our design engineers combine traditional vibrating technology with cutting edge design techniques to produce products that are robust, reliable, efficient and cost-effective,” he concludes.

Ends

Notes to the Editor

To download hi-res images for this release, please visit http://media.ngage.co.za and click the Aury Africa link to view the company’s press office.

About Aury Africa

Aury Africa's goal is to provide the best innovative screening and vibrating equipment solutions and services to the African mining market. Aury Africa takes advantage of the economies of scale provided by large-scale Chinese production from its ISO-9001 accredited sister company, Aury (Tianjin), with the aid and assistance of technical know-how developed in Australia and South Africa.

Aury also has a sound research and design capability, backed up by the technical expertise of a number of engineers who boast extensive experience in vibration technology within the mining sector. Aury design engineers think outside the box to provide traditional vibrating technology with leading edge thinking and design techniques to produce innovative capital equipment that is superior to anything found within the market today.

Aury Africa Contact Details

Matthew van Buuren

Sales and Marketing Administrator

Tel: (011) 026 6642

Email: matt [at] auryafrica [dot] co [dot] za

Web: www.auryafrica.co.za

Media Contact

Ashleigh Wilson

NGAGE Public Relations

Phone: (011) 867 7763

Fax: 086 512 3352

Cell: 072 626 7401

Email: ashleigh [at] ngage [dot] co [dot] za

Web: www.ngage.co.za

Browse the NGAGE Media Zone for more client press releases and photographs at http://media.ngage.co.za