Rio-Carb enables the 'Rapid Removal' of liners through its new system

| Rio-Carb enables the 'Rapid Removal' of liners through its new system_approved | 17.82 KB | Download | |

| The bolt is Chromium Carbide (CrC) hard-faced and galvanised. The removal tool prevents the bolt from turning while the nut is b | 1.23 MB | Download | |

| The company's revolutionary Rapid Removal system, which was officially launched in the local market in August 2013 | 1.11 MB | Download | |

| The Rapid Removal bolts are supplied free with the removal tool, which will lower cost | 973.13 KB | Download | |

| The RR system consists of a countersunk nibbed bolt with a 5 mm slot in the end. The bolt is Chromium Carbide (CrC) hard-faced a | 965.86 KB | Download | |

| The system also eliminates the need for an extra operator to work inside the chute during the liner removal process | 1.3 MB | Download |

PRESS RELEASE

Rio-Carb enables the 'Rapid Removal' of liners through its new system

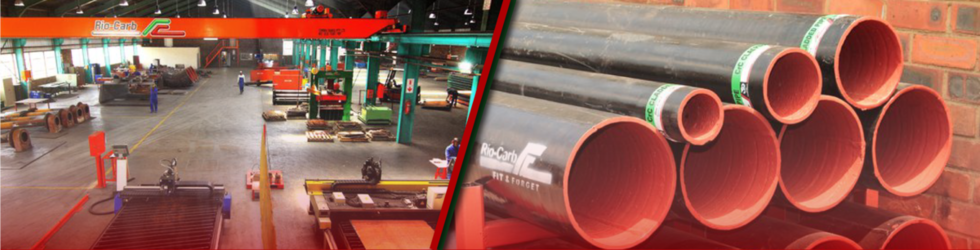

26 September, 2013: Top liner plate expert Rio-Carb has eliminated the costly and time-consuming process of liner replacement, through the introduction of the company's revolutionary Rapid Removal system, which was officially launched in the local market in August 2013.

Rio-Carb director Martin Maine notes that the Designed Registered Rapid Removal (RR) system incorporates a specialised M16 countersunk nibbed bolt and removal tool that entirely eliminate the need for grinding and cutting for the removal of used liner plates.

"The RR system consists of a countersunk nibbedbolt with a 5 mm slot in the end. The bolt is Chromium Carbide (CrC) hard-faced and galvanised. The removal tool prevents the bolt from turning while the nut is being threaded off," he explains.

According to Maine, the system also eliminatesthe need for an extra operator to work inside the chute during the liner removal process. "The entire operation is done from the outside, thereby improving turnaround times while minimising labour costs and the risk of injury."

He adds that Rio-Carb has also developed a machined plasma-cut countersunk hole cutting system that requires no insert, where the hard-faced head of the anchoring bolt forms a flush surface of hard CrC for minimum flow disturbance.

Maine states that the Rio-Carb Rapid Removal system serves a complementary add-on to the company's industry-leading CrC liner plates. "Using exclusive MaxCSTechnology, Rio-Carb is able to take the properties of CrC and cast it via welding process onto a mild steel backing plate, which gives it an optimum hardness of 58 RC, with flexibility for moulding and shaping."

Rio-Carb's CrC plates have been proven in laboratory testing to provide up to ten times the wear resistance against abrasion than the industry-standard 400 and 500 BHN steels, which are also susceptible to annealing when heated to 250°C or more.

Maine highlights the fact that the Rapid Removal system will be incorporated into the price of the CrC liners’ holes, thereby providing the end-user with a comprehensive liner kit. "The Rapid Removal bolts are supplied free with the removal tool, which will lower costs, as the liners are now supplied as a complete kit, including; countersunk nib hard-faced bolts, nuts and washers."

Looking to the future, Maine believes that the introduction of the Rapid Removal system to the local market will consolidate Rio-Carb's reputation for being recognised as the leading provider of liner plate solutions for heavy materials handling applications in the mining and resources industries.

"Continuous technological innovation has resulted in measurable and consistent growth for Rio-Carb. The introduction of the Rapid Removal system is another step forward in our quest to remain the outright market leaders in the development and supply ofliner plate solutions," he concludes.

Ends

Notes to the Editor

There are numerous photographs specific to this press release. Please visit http://media.ngage.co.za and click the Rio-Carb link.

About Rio-Carb

Rio-Carb manufactures wear-resistant Chromium Carbide clad liner plates for heavy materials handling applications in the mining and allied resources industries. The company was initially motivated by Martin Maine, who had experience in the welding and manufacturing industries. He was importing the current product from Australia, and saw the opportunity to establish local manufacture in 1982, when Rio-Tinto had ambitions to establish manufacturing companies allied to mining, and therefore, financed and capitalised the new Rio-Carb for local manufacture. After being in the Rio-Tinto (SA) stable for 16 years, there was a management buy-out by the existing and current share-holders.

Rio-Carb Contact

Martin Maine

Rio-Carb director

Phone: (011) 908 1014

Fax: (011) 908 4139

Email: info [at] riocarb [dot] co [dot] za

Media Contact

Benjamin Iwisi

NGAGE Public Relations

Phone: (011) 867-7763

Fax: 086 512 3352

Cell: 076 263 2001

Email: benjamin [at] ngage [dot] co [dot] za

Web: www.ngage.co.za

Browse the Ngage Media Zone for more client press releases and photographs at http://media.ngage.co.za