Moulding a more competitive future through local manufacture

| Moulding a more competitive future through local manufacture | 15.43 KB | Download | |

| All of the Aury Africa PU panels are manufactured to ISO-9001 quality standards in China | 3.67 MB | Download | |

| Aury Africa MD Mark Houchin | 4.06 MB | Download | |

| One of the panels supplied by Aury Africa is the Non-Blinding panel | 2.08 MB | Download | |

| The underside of a Polyurethane VR panel 305 x 305 | 4.6 MB | Download |

Aury Africa MD Mark Houchin indicates that the company is currently in the process of importing the injection moulding machine from China, which is expected to be fully installed and commissioned at Aury Africa’s Johannesburg-based facility by end-2015.

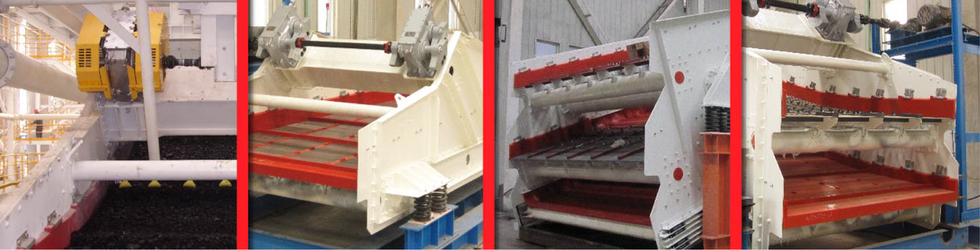

Houchin reveals that PU panels for screening and vibrating equipment are popular across a variety of industries, particularly those that screen materials such as quartz, silica sand and gravel, in addition to those that require panels for dewatering purposes.

“This is a highly-competitive and price-sensitive market. We are planning to take advantage of this price-sensitivity with the introduction of our PU injection mould machine, which will greatly reduce our overhead costs and, in time, is expected to grow our market share substantially,” he states.

The Aury Africa range of PU products that are currently imported, and are due to be manufactured locally with the new injection moulding machine, includes;

- Modular wedge wire panels

- PU cross-tensioned screen cloths

- PU long slots

- Punch plate screen panels with PU borders in 305 mm x 305 mm and 305 mm x 610 mm

- PU screens in 305 mm x 305 mm and 305 mm x 610 mm

- Wedge wire screen panels with PU borders in 305 mm x 305 mm and 305 mm x 610 mm

- PU panels in 305 mm x 305 mm and 305 mm x 610 mm, including pin and sleeve

“These products, which are also available in blank or solid panels, are all manufactured to ISO-9001 quality standards in China. By manufacturing these top-selling products locally, we will also reduce downtime for our customers, while sparking the potential for long-term job creation,” adds Houchin.

What’s more, Aury Africa offers a hybrid fixing system that allows its PU panels to be installed alongside existing panels. “This hybrid fixing system has allowed customers to freely choose which supplier they use, as they are no longer bound by a patent or a specific structure,” Houchin explains.

With a large and expanding footprint across Southern Africa, Aury Africa continues to innovate to provide products and services that satisfy current customer requirements while creating a demand from new customers. “Customers can see the benefits of using PU, and our market share continues to grow. That, combined with our focus on quality, service and price, puts Aury Africa ahead of the curve in servicing our market sectors,” Houchin concludes.

Ends

Notes to the Editor

To download hi-res images for this release, please visit http://media.ngage.co.za and click the Aury Africa link to view the company’s press office.

About Aury Africa

Aury Africa's goal is to provide the best innovative screening and vibrating equipment solutions and services to the African mining market. Aury Africa takes advantage of the economies of scale provided by large-scale Chinese production from its ISO-9001 accredited sister company, Aury (Tianjin), with the aid and assistance of technical know-how developed in Australia and South Africa.

Aury also has a sound research and design capability, backed up by the technical expertise of a number of engineers who boast extensive experience in vibration technology within the mining sector. Aury design engineers think outside the box to provide traditional vibrating technology with leading edge thinking and design techniques to produce innovative capital equipment that is superior to anything found within the market today.

Aury Africa Contact Details

Matthew van Buuren

Sales and Marketing Administrator

Tel: (011) 026 6642

Email: matt [at] auryafrica [dot] co [dot] za

Web: www.auryafrica.co.za

Media Contact

Ashleigh Wilson

NGAGE Public Relations

Phone: (011) 867 7763

Fax: 086 512 3352

Cell: 072 626 7401

Email: ashleigh [at] ngage [dot] co [dot] za

Web: www.ngage.co.za

Browse the NGAGE Media Zone for more client press releases and photographs at http://media.ngage.co.za