Aury Africa refines coal-sample testing for ‘smart’ dry sorting technology

| Aury Africa refines coal-sample testing for smart dry sorting technology_Approved | 32 KB | Download | |

| WMP Consultants has developed a proprietary testing procedure. | 3.31 MB | Download | |

| Aury Africa is launching the TDS technology in Africa. | 2.54 MB | Download | |

| A sample from a discard dump in KwaZulu-Natal has been tested successfully. | 2.98 MB | Download | |

| Local coal samples have been tested on the TDS in China. | 2.73 MB | Download | |

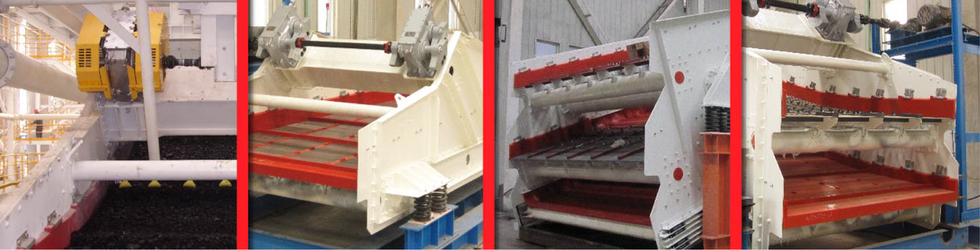

| The Telligent Dry Separator (TDS) at Meiting Technology in China. | 2.68 MB | Download |

Weatherby has refined the procedure to test coal samples in the TDS, characterising all of the components of the sample prior to a full test. “I changed the sample procedure in such a way that we can actually characterise the various elements of the coal seam before we apply the necessary algorithm, thereby giving a much better calibration curve.”

As a result, Aury Africa is in the process of sending a 20 t bulk sample to China for validation of the test initial results, followed by a further six run-of-mine (ROM) samples of discard and coal-recovery samples from various customers.

A particularly exciting development has been the successful testing of a sample from a discard dump in KwaZulu-Natal, containing a mixture of bituminous and anthracite coal from two separate mining streams. The TDS was able to clearly differentiate the two materials in the sample, which means that discard dumps can be turned into potential sources of additional revue for mining operations.

The fact that the TDS is not water-based not only reduces the footprint of mineral-processing plants due to the downscaling of the Dense Medium Separation (DMS) circuit as a result, it also means that slurry material is reduced drastically, thereby offering a significant environmental benefit, in addition to overall cost-savings.

The TDS was developed by Meiteng Technology in 2015. Aury Africa launched the technology locally at the South African Coal Processing Society’s biennial conference in Secunda in September 2017. At that time, three operating mines in China were using the equipment, which is now being commonly applied globally as far afield as Mongolia.

The TDS constitutes intelligent dry separation technology. Essentially coal is conveyed on an enclosed, single-layered conveying system that incorporates dual X-ray technology. It can be retrofitted to an existing coal-processing plant in various configurations.

The system features image-identification technology, with the separator accurately identifying and separating coal and its components, without using water or any other medium. There is also no slime generation, with the TDS subsequently producing a higher yield of coarse coal at low operational cost at an increased return-on-investment, compared to conventional process systems.

The technology can process 300 mm to 50 mm and 150 mm to 25 mm raw coal, with an upper throughput of about 400 tph. The higher tonnage output makes the TDS more efficient compared to competitor dry sorter technology. Aury Africa is continuously striving to improve the technology’s separation capabilities in order to achieve coal sizing down to 12 mm.

The TDS is fully automated and modular, and also self-diagnostic. The longer the unit runs, the more accurate it becomes. “The margin of reject material compared to coal is reduced, as the TDS learns and adapts continuously,” Aury Africa Managing Director Sydney Parkhouse concludes.

Ends

Connect with Aury Africa on Social Media to receive the company’s latest news

Facebook: https://www.facebook.com/AuryAfrica/

LinkedIn: https://www.linkedin.com/in/aury-africa-0879850954/

Notes to the Editor

To download hi-res images for this release, please visit media.ngage.co.za and click the Aury Africa link to view the company’s press office.

About Aury Africa

Aury Africa’s goal is to provide the best innovative screening and vibrating equipment solutions and services to the African mining market. Aury Africa takes advantage of the economies of scale provided by large-scale Chinese production from its ISO-9001 accredited sister company, Aury (Tianjin), with the aid and assistance of technical know-how developed in Australia and South Africa.

Aury also has a sound research and design capability, backed up by the technical expertise of a number of engineers who boast extensive experience in vibration technology within the mining sector. Aury design engineers think outside the box to provide traditional vibrating technology with leading-edge thinking and design techniques to produce innovative capital equipment that is superior to anything on the market today.

Aury Africa Contact

Sydney Parkhouse

Tel: (011) 026-6642

Email: syd [at] auryafrica [dot] co [dot] za

Web: www.auryafrica.co.za

Media Contact

Nomvelo Buthelezi

NGAGE Public Relations

Phone: (011) 867-7763

Fax: 086 512 3352

Cell: 083 4088 911

Email: nomvelo [at] ngage [dot] co [dot] za

Web: www.ngage.co.za

Browse the NGAGE Media Zone for more client press releases and photographs at media.ngage.co.za