The importance of using genuine CrC products

PRESS RELEASE

The importance of using genuine CrC products

29 September, 2014: When manufactured and handled correctly, Chromium (CrC) can last up to eight times longer than traditional materials used in the production of chute liners, which significantly extends the life of the product. It is, therefore, essential to make use of manufacturers that are fully equipped to manufacture genuine quality CrC.

CrC is becoming an increasingly popular product in industry due to its low maintenance requirements and long life-span when handled correctly. The manufacturing of CrC has vastly increased since the product was first introduced to the market. Advances in technology and variations in manufacturing methods have been developed since the original launch of this product.

Rio-Carb director Martin Maine reveals that the manufacturing methodology can affect the quality, consistency, integrity and wear properties of liner plates. He stresses the importance of using certified products that use CrC in their materials handling process.

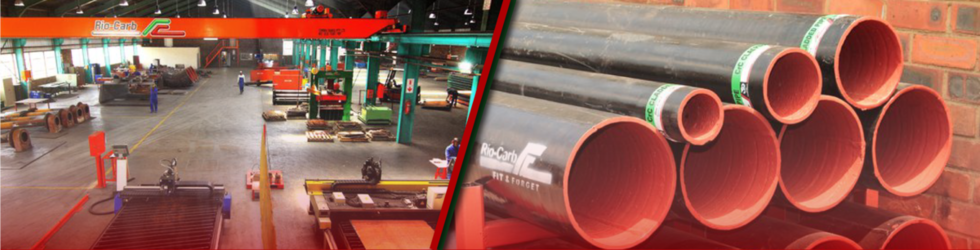

“Rio-Carb manufactures a wide range of innovative CrC products for the South African heavy materials handling industry, and is the only local liner plate and equipment manufacturer whose welding standards are compliant with the internationally-recognised specifications established by the American Welding Society (AWS),” he explains.

According to Maine, South African welding standards do not make provisions for CrC welding, which requires specialised techniques. “The welding of CrC faces many risks if not carried out in accordance to certain specifications. The biggest challenge with CrC is to get the weld smooth, as a rough weld immediately creates more cavities and disturbances in the flow. Customers need to be wary of companies that do not have certified welding processes, as this may cause future problems.”

Maine believes that there is a general lack of knowledge and understanding about the use of CrC in the local industry. “As a result, Rio-Carb has launched a fabrication facility with state-of-the-art equipment and technology, which we hope will provide designers and users of CrC fist-hand experience and detailed information regarding the application of this unique material.”

Laboratory testing has proven that CrC provides eight to ten times the wear resistance against abrasion, when compared to industry-standard 400 and 500 BHN steel, which are susceptible to annealing when heated to 350 °C or more. CrC has hard chrome carbides in a steel base and this contributes to a longer life span and reduced maintenance.

Maine points out that it is important for companies to not just supply CrC products, but to also be able to process them efficiently and professionally too. “As the balance between cost effectiveness and reliability becomes increasingly important, industries will be looking for new and improved methods to effectively transport abrasive materials, and therefore good quality and genuine CrC products are needed,” he concludes.

Ends

Notes to the Editor

There are numerous photographs specific to this press release. Please visit http://media.ngage.co.za and click the Rio-Carb link.

About Rio-Carb

Rio-Carb manufactures wear-resistant Chromium Carbide clad liner plates for heavy materials handling applications in the mining and allied resources industries. The company was initially motivated by Martin Maine, who had experience in the welding and manufacturing industries. He was importing the current product from Australia, and saw the opportunity to establish local manufacture in 1982, when Rio-Tinto had ambitions to establish manufacturing companies allied to mining, and therefore, financed and capitalised the new Rio-Carb for local manufacture. After being in the Rio-Tinto (SA) stable for 16 years, there was a management buy-out by the existing and current share-holders.

Rio-Carb Contact

Martin Maine

Rio-Carb director

Phone: (011) 908 1014

Fax: (011) 908 4139

Email: info [at] riocarb [dot] co [dot] za

Media Contact

Bridgette Macheke

NGAGE Public Relations

Phone: (011) 867-7763

Fax: 086 512 3352

Cell: 083 260 8214

Email: renay [at] ngage [dot] co [dot] za

Web: www.ngage.co.za

Browse the Ngage Media Zone for more client press releases and photographs at http://media.ngage.co.za