Shaking up the local market with customised vibrating screens

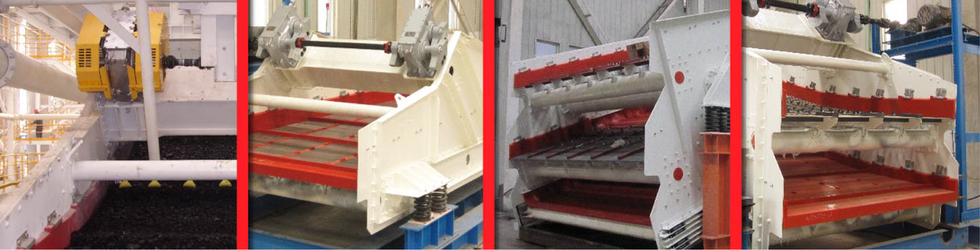

Aury Africa is the exclusive local distributor of the Aury vibrating screen range, available in sizes from 1,2 m x 2,4 m, up to 4,9 m x 7,3 m. According to Aury Africa MD Mark Houchin, the most commonly-used screen size in the local market is up to 2,4 m wide – far below the Chinese and Australian sizes of 3,6 m and wider.

“We discovered that the Aury screens between 1,2 m and 2,4 m were slightly over-designed in terms of their heavy-duty capabilities, particularly for the South African coal market. Screens this size do not require the same heavy-duty characteristics as the larger ones,” he explains.

As a result, Aury Africa requested that its China-based factory manufacture a fit-for-purpose screen to accommodate the duty tolerances for the 1,2 m to 2,4 m range only. The screens were introduced in early-2015, and can ensure 30 to 40 percent savings over the current screen prices.

“This is a major advantage in challenging economic conditions, and is achieved by reducing the polyurethane coating on the cross beams from 6 mm to 2 mm. A 6 mm polyurethane coating is applied to a 4,9 m screen to accommodate considerably larger volumes. This is extra built-in capacity that is simply not required on smaller screens,” states Houchin.

Another fit-for-purpose Aury vibrating screen customisation is the replacement of exciter drives with outer balance electric motors. An exciter drive involves a single motor driving through a cardan shaft. It is essentially a gear box that has counter weights that spin to create thrust on the screen. In contrast, an outer balance motor is typically based directly on the screen drive beam.

Houchin notes that the out of balance electric motors are situated on the drive beam, and vibrate directly on the screen. “These motors are considerably cheaper to purchase, and reduce the overall cost of the screen by another 10 to 15 percent.”

Despite these modifications, Houchin stresses that there is no negative impact on quality or efficiency. “There is no compromise on quality, all we have done is shed some weight and replaced the exciters with out of balance motors to make the screens better-suited for local operations.”

He reveals that the fundamental design aspects remain unchanged. “The same side plates, huck bolting and 305 mm x 305 mm panels are still being used during manufacture. The pin and sleeve fitting system has been redesigned, however, to accommodate the reduction in weight.”

Another benefit of the new screens is that they boast a highly-flexible footprint and can be retrofitted into any existing screen footprint. “We are able to modify the footprint to fit any existing screen installation, which results in even greater savings. Most competitors do not offer this service, and operations are forced to do a full replacement, as opposed to a simple modification.”

Houchin believes that the introduction of these customised screens will result in measurable growth for Aury Africa, particularly within in the entry-level coal, diamond and chrome mining sector. “We have received positive feedback and interest from these operations, which place a high priority on quality equipment that is affordable, and the new screen range fits precisely into this category.”

The typical lifespan of an Aury vibrating screen is between 10 and 20 years, depending on operating conditions, care and maintenance. Houchin says: “If consumables are well-maintained and replaced, these screens will operate for the same duration as world-leading brands, at a fraction of the cost.”

Although most customised Aury vibration screens fit into standard 2,5-m-wide shipping containers, Houchin states that larger screens are supplied in flat-packed formation and assembled locally. “An outsourced engineering company is currently responsible for assembly. Should demand for larger screens increase, we will undertake assembly in-house at the Aury Africa facility in Johannesburg.”

Ends

Notes to the Editor

There are numerous photographs specific to this press release. Please visit http://media.ngage.co.za and click the Aury Africa link.

About Aury Africa

Aury Africa's goal is to provide the best innovative screening and vibrating equipment solutions and services to the African mining market. Aury Africa takes advantage of the economies of scale provided by large-scale Chinese production from its ISO-9001 accredited sister company, Aury (Tianjin), with the aid and assistance of technical know-how developed in Australia and South Africa.

Aury also has a sound research and design capability, backed up by the technical expertise of a number of engineers who boast extensive experience in vibration technology within the mining sector. Aury design engineers think outside the box to provide traditional vibrating technology with leading edge thinking and design techniques to produce innovative capital equipment that is superior to anything found within the market today.

Aury Africa Contact Details

Matthew van Buuren

Sales and Marketing Administrator

Tel: (011) 026 6642

Email: matt [at] auryafrica [dot] co [dot] za

Web: www.auryafrica.co.za

Media Contact

Ashleigh Wilson

NGAGE Public Relations

Phone: (011) 867 7763

Fax: 086 512 3352

Cell: 072 626 7401

Email: ashleigh [at] ngage [dot] co [dot] za

Web: www.ngage.co.za

Browse the NGAGE Media Zone for more client press releases and photographs at http://media.ngage.co.za