Rio-Carb successfully revamps storage bins at smelter furnace

| Rio-Carb successfully revamps storage bins at smelter furnace_not approved | 31 KB | Download | |

| Raw material is collected in the storage bins and deposited into the furnace. | 88.44 KB | Download | |

| Rio-Carb has revamped storage bins at a major smelter furnace. | 60.46 KB | Download | |

| The use of CrC material has extended the lifespan of the bins by up to seven years. | 128.93 KB | Download |

The raw materials are collected in the storage bins, and deposited into the furnace in a predetermined mixture. Such has been the success of the project that the wear engineering solutions specialist has become a preferred supplier at the mining operation, and has been awarded another furnace storage-bin upgrade project for 2019, Rio-Carb General Manager Sias Suurd reveals.

This is an ongoing project, with Rio-Carb dating its original involvement to 2006. “We have been involved ever since, first on a small scale, and later when our product proved itself, we became the preferred supplier,” Suurd adds.

“Our client has realised a tremendous cost-saving in that the same items now only have to be replaced every five to seven years, instead of every 18 months to two years. This translates into a substantial saving in downtime, labour costs, and production losses,” Suurd explains. A value-added benefit is that the client can now plan regular proactive maintenance in order to minimise potential breakdowns, and also to take advantage of planned shutdowns.

“The planning usually commences towards the end of a year, that is in terms of initial discussions, any changes to drawings, and then the final quotations. Orders are placed from early in the new year, and delivery obviously takes place before the shutdown commences,” Suurd explains. The shutdowns, which last up to six weeks, are always planned for the winter period.

A particular logistical challenge posed by the latest project was to ensure that sufficient 12 mm plate was on hand when the final order was placed. The high-profile furnace revamp for a major mining house is cementing Rio-Carb’s reputation as a total solutions provider.

“Our strategy focuses on designing A-to-Z wear solutions for mining operations. We now have a foot in the door with this particular client, which will stand us in good stead in securing additional work in the area in the near future,” Suurd concludes.

Ends

Connect with Rio-Carb on Social Media to receive the company’s latest news

Facebook: https://www.facebook.com/RioCarb/

LinkedIn: https://www.linkedin.com/in/rio-carb-pty-ltd-797496108/

Notes to the Editor

To download hi-res images for this release, please http://media.ngage.co.za and click the Rio-Carb link to view the company’s press office.

About Rio-Carb

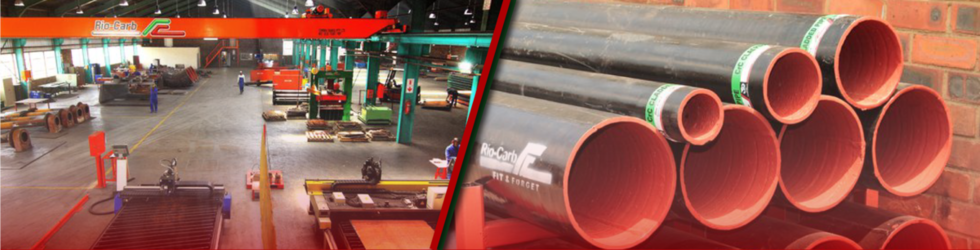

Rio-Carb manufactures wear-resistant Chromium Carbide (CrC) clad liner plates for heavy materials-handling applications in the mining and allied resources industries. With more than 30 years’ experience, the company’s long-life CrC liners have eight to ten times the wear life of industry-standard 400 and 500 BHN steel materials, which reduces operational costs dramatically due to less downtime and change-outs. Rio-Carb has a deep-rooted history in mining, and is able to respond to customers’ needs swiftly in providing cost-effective solutions.

Rio-Carb Contact

Jabu Mlambo

Sales & Marketing Administrator

Phone: (011) 011 6111

Fax: (011) 908 4139

Email: jabu [at] riocarb [dot] co [dot] za

Web: www.riocarb.com

Media Contact

Nomvelo Buthelezi

NGAGE Public Relations

Phone: (011) 867-7763

Fax: 086 512 3352

Cell: 083 408 8911

Email: nomvelo [at] ngage [dot] co [dot] za

Web: www.ngage.co.za

Browse the NGAGE Media Zone for more client press releases and photographs at media.ngage.co.za