Rio-Carb repositions itself as a total wear-solutions provider

| Rio-Carb repositions itself as a total wear-solutions provider_ approved | 28 KB | Download | |

| Rio-Carb’s wear solutions for the mining industry range from bulk materials handling to earthmoving equipment | 341.67 KB | Download | |

| Rio-Carb offers total solutions based on clients’ specific needs and applications | 2.18 MB | Download |

The manufacturer will also focus on ceramic and rubber products, in addition to Chromium Carbide, in a bid to offer hybrid wear solutions that offer the least maintenance and longest equipment uptime, newly-appointed General Manager Sias Suurd explains.

“We look holistically at the problem of wear in the mining industry. Instead of just selling liners to help combat or reduce wear, our new mindset is to offer a total solution based on the client’s specific needs and applications,” Suurd elaborates.

“Our aim is to expand our product range in order to be able to cater for a total spectrum of wear solutions in the mining industry, from bulk materials handling to earthmoving equipment. There are some applications where Chromium Carbide on its own may not be the most cost-effective answer. Our aim is to become flexible enough in order to be able to offer complete solutions.”

Whereas Rio-Carb in the past has installed liners under its slogan of ‘fit-and-forget’, the company will in future capitalise on solutions provided in order to help promote best practice in the mining industry through successful case studies. “By focusing on wear itself, our clients are assured of solutions that will contribute dramatically to their bottom line. This is a win-win situation for ourselves and our clients.”

Suurd is embarking on an extensive roadshow to Rio-Carb’s major clients in order to introduce himself in his new role, and to promote the company’s new solutions-based approach. “We have longstanding relationships with many of our biggest clients, which have been critical in establishing us as the leading player in this highly-competitive market.”

In terms of market growth, Rio-Carb will focus on opportunities in Namibia, Zambia, Botswana and Mozambique, as part of its overall strategy to expand its reach in Southern Africa. The manufacturer will also look at expanding its product range to cater for additional applications and requirements, and to increase the uptake of Chromium Carbide in the mining industry.

Ends

Notes to the Editor

To download hi-res images for this release, please http://media.ngage.co.za and click the Rio-Carb link to view the company’s press office.

About Rio-Carb

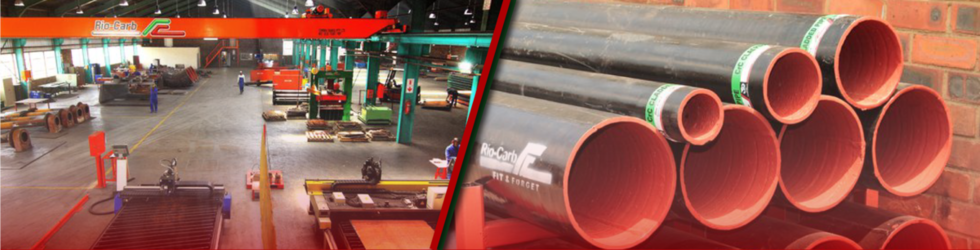

Rio-Carb manufactures wear-resistant Chromium Carbide (CrC) clad liner plates for heavy materials-handling applications in the mining and allied resources industries. With more than 30 years’ experience, the company’s long-life CrC liners have eight to ten times the wear life of industry-standard 400 and 500 BHN steel materials, which reduces operational costs dramatically due to less downtime and change-outs. Rio-Carb has a deep-rooted history in mining, and is able to respond to customers’ needs swiftly in providing cost-effective solutions.

Media Contact

Mmule Ncongwane

NGAGE Public Relations

Phone: (011) 867-7763

Fax: 086 512 3352

Cell: 083 661 8751

Email: mmule [at] ngage [dot] co [dot] za

Web: www.ngage.co.za

Browse the NGAGE Media Zone for more client press releases and photographs at media.ngage.co.za