Rio-Carb R-C700 wear liner plate is the ‘green steel’ alternative

| Rio-Carb R-C700 wear liner plate is the green steel alternative_approved | 38 KB | Download | |

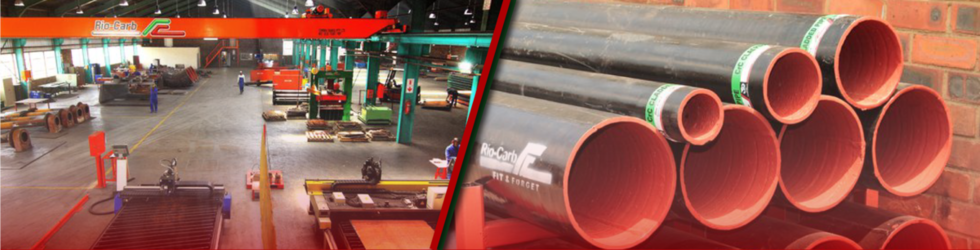

| The state-of-the-art Rio-Carb manufacturing facility in Alrode, Gauteng | 14.19 MB | Download | |

| Modular chutes and bins from Rio-Carb using R-C700 wear panels can be assembled on-site | 1.3 MB | Download | |

| R-C700 liner plate from Rio-Carb for rapid maintenance of higher-wear areas | 929.36 KB | Download | |

| Rio-Carb uses R-C700 wear panels for fully modular chutes and bins | 926.54 KB | Download | |

| Rio-Carb Design Engineer Roshalan Govender | 2.06 MB | Download | |

| Rio-Carb Marketing and Branding Director Jabulile Mlambo | 1.18 MB | Download |

“An indirect benefit due to its immediate and obvious carbon reduction is that transportation of all implied products is reduced by the same factor, thus saving significantly on indirect emissions,” comments Rio-Carb Design Engineer Roshalan Govender.

Reducing GHG to combat climate change is an important goal of the 2015 Paris Agreement, whereby 190 countries have committed to carbon neutrality by 2050. A major focus in this drive is the steel industry, which is among the top three producers of carbon dioxide, a major contributor to global warming.

The World Steel Association (WSA) reports that every ton of steel produced in 2019 emitted approximately three tonnes of carbon dioxide on average, equivalent to about 8% of global CO2 emissions. In addition, the WSA highlights that recycling steel plates produces three times the mass in GHG, or three tonnes for every kilogram of steel that is melted. Thus on a chute with 1 000 tonnes of R-C700 liners, the total lifespan saving in terms of GHG is an astonishing 21 tonnes.

It is for this reason that Rio-Carb has also aligned itself with the ISO 14001 environmental management system to benchmark its manufacturing processes. The aim is to manufacture R-C700 long-life wear liners that conform to the highest possible quality standards, from the stainless steel studs to the Rapid Removal system, tight cutting tolerances and ease of movement, coupled with plasma-etched part numbers for easy identification and replacement.

“An important criterion for ISO 14001 is resource conservation. Our long-life wear solutions play a critical role in boosting materials-handling efficiency and cost-effectiveness,” comments Rio-Carb Marketing and Branding Director Jabulile Mlambo.

In particular the OEM will be looking to implement ISO 14062, which focuses on concepts and current practices relating to the integration of environmental aspects into product design and development. “Such standards offer an environmentally-positive option to the mining, steel and cement industries, all of which are under severe pressure from both shareholders and the government to drastically reduce their carbon footprint,” explains Mlambo.

Therefore Rio-Carb has launched a campaign to make its customers and the broader industry aware of the negative impact of GHG and how this risk can best be mitigated. All R-C700 wear plates produced by Rio-Carb will carry a green four-sided logo illustrating the concepts of reduction, reuse and recycling.

This will also assist in positioning Rio-Carb as a total solutions provider, with CrC providing the lowest total cost of ownership for complete wear solutions in the mining industry. “We believe that this is the most cost-effective material to combat severe wear. It does present a challenge in terms of those customers who are set in their ways. However, one of our biggest opportunities is to change the mindset of these customers and to show them the myriad advantages of using CrC, which also makes a significant contribution to carbon reduction in line with our environmental obligations,” concludes Mlambo.

Ends

Connect with Rio-Carb on Social Media to receive the company’s latest news

Facebook: https://www.facebook.com/RioCarb/

LinkedIn: https://www.linkedin.com/in/rio-carb-pty-ltd-797496108/

Notes to the Editor

To download hi-res images for this release, please http://media.ngage.co.za and click the Rio-Carb link to view the company’s press office.

About Rio-Carb

Rio-Carb manufactures wear-resistant Chromium Carbide (CrC) clad liner plates for heavy materials-handling applications in the mining and allied resources industries. With more than 30 years’ experience, the company’s long-life CrC liners have eight to ten times the wear life of industry-standard 400 and 500 BHN steel materials, which reduces operational costs dramatically due to less downtime and change-outs. Rio-Carb has a deep-rooted history in mining, and is able to respond to customers’ needs swiftly in providing cost-effective solutions.

Rio-Carb Contact

Jabu Mlambo

Branding Manager

Phone: (011) 011 6111

Fax: (011) 908 4139

Email: jabu [at] riocarb [dot] co [dot] za

Web: www.riocarb.com

Media Contact

Renay Tandy

NGAGE Public Relations

Phone: (011) 867-7763

Fax: 086 512 3352

Cell: 082 562 5088

Email: renay [at] ngage [dot] co [dot] za

Web: www.ngage.co.za

Browse the NGAGE Media Zone for more client press releases and photographs at http://media.ngage.co.za