Rio-Carb plans to build on its successes and achievements in 2016

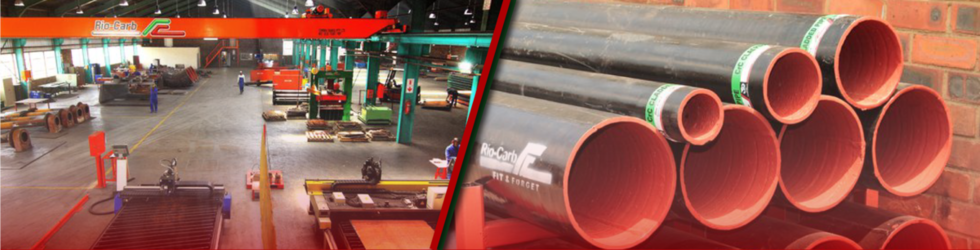

The company had a particularly noteworthy 2016, remarks Director Martin Maine. “We were swimming against the current, but had a great year. We were awarded ISO 9001 certification, launched new products, and improved our internal and manufacturing processes.” Going forward, the plan is to add additional state-of-the-art equipment to its fully-automated welding facilities.

Last year, Rio-Carb embarked on its ISO 9001 accreditation process to assure customers of the quality of its products. “Our products are highly specialised, and not just off-the-shelf. We deal with many major customers in the mining industry, where such accreditation is mandatory. We are very proud of having achieved this quality assurance,” Director Jenny Maine comments, who oversaw the ISO implementation at Rio-Carb.

A renewed focus in 2016 was applying the benefits of CrC to Rio-Carb’s pipe range, which is more robust than ceramics and longer-lasting than rubber. This makes them ideal for abrasive materials such as slurries.

The bore of these pipes is cladded with 4 mm to 6 mm CrC, in an extremely smooth and even layer for good flow results. The pipes, available in 3 m lengths, can be fabricated into bends, T-pieces and customised shapes. A special in-house designed plasma cutting rotator, using X, Y, Z geometry, cuts within 1 mm tolerances.

Looking ahead at 2017, Maine says Rio-Carb remains positive, and will continue to face any challenges head on. “We would like to take this opportunity to thank all of our clients for their ongoing loyal support, and choosing Rio-Carb as trusted partner for all their wear solutions based on our R-C700 CrC liners and pipes.”

Maine stresses that Rio-Carb will remain focused on product innovations in the year ahead, so as to be able to meet more of its customers’ materials-handling needs. “We always strive for continuous improvement on our products and systems.”

A notable trend in the mining industry going forward, according to Maine, is an increased emphasis on automation and technology. “We are ideally placed to be able to offer our customers complete solutions in order to boost their productivity and reduce downtime,” Maine concludes.

Ends

Notes to the Editor

To download hi-res images for this release, please http://media.ngage.co.za and click the Rio-Carb link to view the company’s press office.

About Rio-Carb

Rio-Carb manufactures wear-resistant Chromium Carbide (CrC) clad liner plates for heavy materials-handling applications in the mining and allied resources industries. With more than 30 years of experience, the company’s long-life CrC liners have 8 to 10 times the wear life of industry-standard 400 and 500 BHN steel materials, which dramatically reduces operational costs as a result of less downtime and change-outs. Rio-Carb has a deep-rooted history in mining, and is able to swiftly respond to customers' needs in providing cost-effective solutions.

Rio-Carb Contact

Martin Maine

Director

Phone: (011) 908 1014

Fax: (011) 908 4139

Email: info [at] riocarb [dot] co [dot] za

Web: www.riocarb.co.za

Media Contact

Judette Olivier

NGAGE Public Relations

Phone: (011) 867 7763

Fax: 086 512 3352

Cell: 072 199 8734

Email: judette [at] ngage [dot] co [dot] za

Web: www.ngage.co.za

Browse the NGAGE Media Zone for more client press releases and photographs at media.ngage.co.za