Rio-Carb maintains internationally-recognised AWS certification

| Rio-Carb maintains internationally-recognised AWS certification Press Release | 14.14 KB | Download |

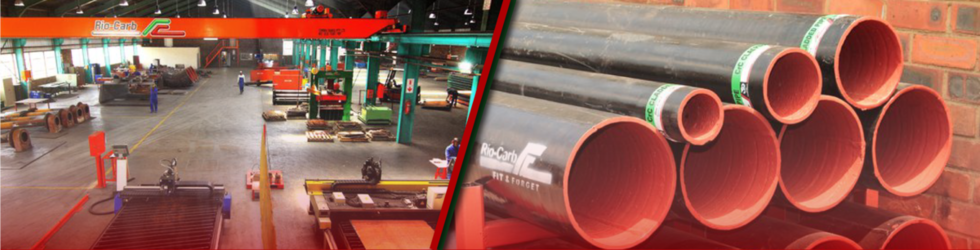

World-class welding standards have enabled top liner-plate expert Rio-Carb to manufacture a wide variety of long-life Chromium Carbide (CrC) liner plates, chutes, hoppers and slides for the South African heavy materials handling industry.

Rio-Carb director Martin Maine points out that the company is the only liner plate manufacturer in South Africa whose welding standards are compliant with the internationally-recognised specifications drawn up by the American Welding Society (AWS).

“The AWS is a non-profit organisation that was established with a goal to advance the science, technology and application of welding and related joining disciplines. Today, the AWS serves more than 66 000 members worldwide, and is recognised as the global authority on welding standards, and Rio-Carb is exceptionally proud to be certified by this institution,” he explains.

All of Rio-Carb’s welding techniques are independently certified in laboratory testing facilities adds Maine. “The company certifies all of our specifications, not only to AWS standards, but also to additional standards that include; the welding procedures specification (WPS), procedure qualification record (PQR) and the welder’s qualifications certificate (WQC). This provides our customers with the peace-of-mind that that they are being provided with products that meet the highest international standards of quality, which are independently verified by an external source,” he continues.

Maine highlights the fact that welding presents certain challenges due to the high contents of carbon and chromium on the hard facing deposit, which can lead to product failure if not done correctly. “End-users need to be wary of companies whose welding processes are not certified. Although the product may be cheaper, it does not meet the required international specs, and will actually work out more expensive as a result of unscheduled downtime and maintenance on machinery.”

Maine admits that welding standards in South Africa do not yet make provision for Chromium Carbide welding. “Local welding standards are predominantly based on carbon-based martensitic 400 and 500 BHN materials. Chromium Carbide, however; has been proven in laboratory testing to provide up to ten times the wear resistance against abrasion than the industry-standard 400 and 500 BHN steel, which are susceptible to annealing when heated to 350°C or more.”

When used correctly, Maine points out that Chromium Carbide is literally a ‘wonder material’. “By making use of exclusive technology, Rio-Carb is able to take the properties of the material and cast it via welding process onto a mild steel backing plate, which gives it an optimum hardness of 54 RC, and additional flexibility for moulding and shaping. Rio-Carb CrC materials also do not lose their hardness at higher temperatures, and are unaffected by heating and cooling cycles.”

Maine notes that as the only company in South Africa certified for Chromium Carbide welding by the AWS, Rio-Carb has placed itself in a dominant position within the local market. “AWS certification ensures that Rio-Carb is able to comply with any welding standard that is laid down in South Africa at any given time. What’s more, Chromium Carbide is the new-age material of the 21st century, and as the leading manufacturer and internationally-certified welder of this material, Rio-Carb will plans to consolidate on its current successes moving forward, by continuing to set industry trends for competitors to follow,” he concludes.

Ends

Notes to the Editor

There are numerous photographs specific to this press release. Please visit http://media.ngage.co.za and click the Rio-Carb link.

About Rio-Carb

Rio-Carb manufactures wear-resistant Chromium Carbide clad liner plates for heavy materials handling applications in the mining and allied resources industries. The company was initially motivated by Martin Maine, who had experience in the welding and manufacturing industries. He was importing the current product from Australia, and saw the opportunity to establish local manufacture in 1982, when Rio-Tinto had ambitions to establish manufacturing companies allied to mining, and therefore, financed and capitalised the new Rio-Carb for local manufacture. After being in the Rio-Tinto (SA) stable for 16 years, there was a management buy-out by the existing and current share-holders.

Rio-Carb Contact

Martin Maine

Rio-Carb director

Phone: (011) 908 1014

Fax: (011) 908 4139

Email: info [at] riocarb [dot] co [dot] za

Media Contact

Benjamin Iwisi

NGAGE Public Relations

Phone: (011) 867-7763

Fax: 086 512 3352

Cell: 076 263 2001

Email: benjamin [at] ngage [dot] co [dot] za

Web: www.ngage.co.za

Browse the Ngage Media Zone for more client press releases and photographs at http://media.ngage.co.za