Rio-Carb is a one-stop shop for complete wear solutions

| Rio-Carb is a one-stop shop for complete wear solutions-approved | 29 KB | Download | |

| Rio-Carb has designed hybrid liner packages for haul trucks in addition to upgrading its liner packaging &entering into ceramics | 34.15 KB | Download | |

| Rio-Carb offers a modular chute service for minerals-processing plants. | 25.78 KB | Download | |

| Rio-Carb Director Sias Suurd | 71.74 KB | Download |

These innovations include modular chutes, the design of hybrid liner packages for haul trucks, upgraded liner packaging, and an entry into ceramics. “We have started to look at various materials, and hence we have expanded to supply ceramics as part of our product range,” Rio-Carb Director Sias Suurd explains.

“We are focusing our sales strategy to design A-to-Z wear solutions for operations – for example, right from where the ground-breaking is taking place, to where the final product is loaded.” However, Suurd stresses that Rio-Carb will still focus on its signature Chromium Carbide material.

“We believe that this is the most cost-effective material to combat severe wear. This poses a challenge in terms of those customers who are set in their ways. However, one of our biggest opportunities is to change the mindset of these customers, and to show them the myriad advantages of using Chromium Carbide.

In areas where wear is not severe, we will look at other materials that are more cost-effective for the application at hand.” This means that Rio-Carb will focus on offering total wear solutions. “We want to be the first people on the phone list when any operation experiences a wear-related problem. We also offer an investigative service whereby we can identify specific wear problems, and provide appropriate recommendations,” Suurd highlights.

Rio-Carb is also looking at expanding the use of Chromium Carbide into other areas. “Some applications are common globally, but have not yet been adopted locally. We want to bring this to the attention of all operations managers, and thereby assist in promoting best practice in South Africa.”

This broader outlook has seen Rio-Carb expand to Namibia, Zambia, and Madagascar. “We recently appointed a representative in Botswana, and will be looking to expand to Lesotho, Zimbabwe, and Mozambique soon.”

While Suurd describes 2017 as “a difficult year with some challenges, we have worked hard to strengthen our team, and to put us in a good position to expand our business in 2018. We aim to retain our customers and to grow our current business.”

For example, Rio-Carb will offer its modular chute design service for the processing-plant market in particular. “We will also strive to build strong relationships with large operations to reduce their operating costs, and thereby increase the efficiency of their operations,” Suurd maintains.

Ends

Notes to the Editor

To download hi-res images for this release, please http://media.ngage.co.za and click the Rio-Carb link to view the company’s press office.

About Rio-Carb

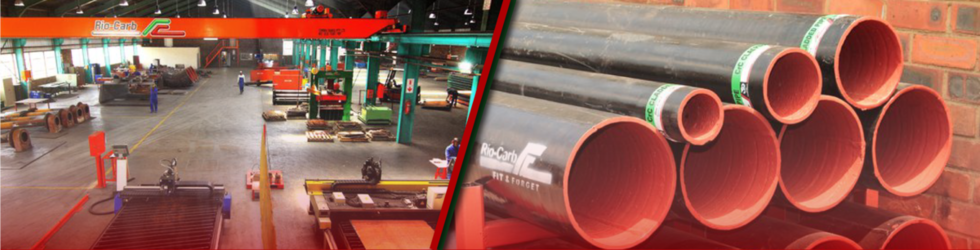

Rio-Carb manufactures wear-resistant Chromium Carbide (CrC) clad liner plates for heavy materials-handling applications in the mining and allied resources industries. With more than 30 years’ experience, the company’s long-life CrC liners have eight to ten times the wear life of industry-standard 400 and 500 BHN steel materials, which reduces operational costs dramatically due to less downtime and change-outs. Rio-Carb has a deep-rooted history in mining, and is able to respond to customers’ needs swiftly in providing cost-effective solutions.

Media Contact

Mmule Ncongwane

NGAGE Public Relations

Phone: (011) 867-7763

Fax: 086 512 3352

Cell: 083 661 8751

Email: mmule [at] ngage [dot] co [dot] za

Web: www.ngage.co.za

Browse the NGAGE Media Zone for more client press releases and photographs at media.ngage.co.za