Rio-Carb internship programme upskills the engineers of tomorrow

PRESS RELEASE

Rio-Carb internship programme upskills the engineers of tomorrow

23 January 2017: Upskilling the engineers of tomorrow is the main aim of an internship programme offered by Rio-Carb, a leading manufacturer of R-C700 CrC wear liners and pipes for heavy materials-handling applications in the mining and allied resources industries.

University of the Witwatersrand (Wits) BSc Mechanical Engineering student Uma Krige has just completed a six-week internship programme at the Alberton manufacturer. “Our aim is to make a meaningful contribution to the development of the industry by upskilling the engineers of tomorrow,” Director Martin Maine comments.

Top achiever Krige impressed Rio-Carb due to her notable academic achievements to date and leadership qualities. The six-week internship gave her invaluable exposure to both production and business processes, in the company of experienced engineers.

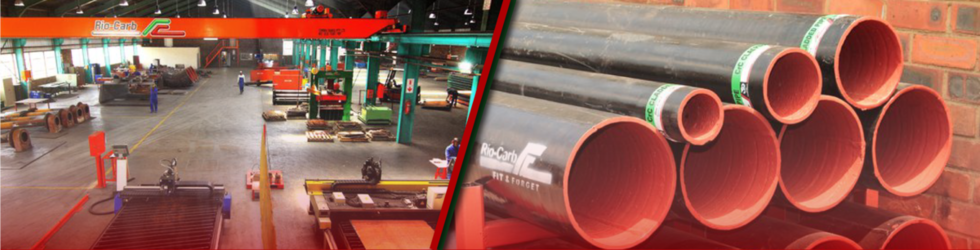

“Rio-Carb is essentially a one-stop shop where interns can learn everything from CAD design to actual engineering production. This is a hands-on, real-life learning environment that gives tertiary students much-needed practical experience,” Maine explains.

Krige stresses that the exposure to a broad-ranging production environment such as at Rio-Carb is rounding her theoretical training at Wits. Apart from being able to see processes such as plasma cutting, welding, grinding, drilling, and sheet-forming first-hand in a highly-automated and bespoke facility, she has also attended client site visits, and even sat in on sales and production meetings.

While it is challenging being a woman in her chosen career path, Krige adds that companies such as Rio-Carb are helping to challenge the status quo in this male-dominated industry. Going forward, Maine says that promising students such as Krige will be offered an opportunity for full-time employment upon successful completion of their studies.

“We also plan to expand our internship programme in the near future, as this represents a significant investment on the part of Rio-Carb in the future of both the industry and the company,” Maine concludes.

Ends

Notes to the Editor

To download hi-res images for this release, please visit http://media.ngage.co.za and click on the Rio-Carb link to view the company’s press office.

About Rio-Carb

Rio-Carb manufactures wear-resistant Chromium Carbide (CrC) clad liner plates for heavy materials-handling applications in the mining and allied resources industries. With more than 30 years’ experience, the company’s long-life CrC liners have eight to ten times the wear life of industry-standard 400 and 500 BHN steel materials, which dramatically reduces operational costs as a result of less downtime and change-outs. Rio-Carb has a deep-rooted history in mining, and is able to swiftly respond to customers' needs in providing cost-effective solutions.

Rio-Carb Contact

Martin Maine

Director

Phone: (011) 908 1014

Fax: (011) 908 4139

Email: info [at] riocarb [dot] co [dot] za

Web: www.riocarb.co.za

Media Contact

Judette Olivier

NGAGE Public Relations

Phone: (011) 867 7763

Fax: 086 512 3352

Cell: 072 199 8734

Email: judette [at] ngage [dot] co [dot] za

Web: www.ngage.co.za

Browse the NGAGE Media Zone for more client press releases and photographs at media.ngage.co.za