Rio-Carb develops chromium carbide impact resistant liner plates

| Rio-Carb develops chromium carbide impact resistant liner plates_approved | 13.2 KB | Download | |

| Chromium carbide impact resistant liner plate | 1.7 MB | Download | |

| Chromium carbide overlay plate is more impact resistant than previous Rio-Carb chromium carbide plates | 1.57 MB | Download | |

| Rio-Carb director Martin Maine | 6.84 MB | Download | |

| The new impact resistant liner plate has a hardness of between 56 and 58 Rockwell C | 1.47 MB | Download |

PRESS RELEASE

Rio-Carb develops chromium carbide impact resistant liner plates

19 March, 2014: Top liner plate expert, Rio-Carb, has developed a new chromium carbide impact resistant liner plate, which allows the plates to be used in areas and industries where previous chromium carbide plates were restricted due to the limited impact resistance of the plates.

Rio-Carb director Martin Maine notes that there was a need to develop a chromium carbide overlay plate that is more impact resistant than previous Rio-Carb chromium carbide plates. “The new impact resistant liner plates were developed by adding more manganese to the existing chromium carbide plate formulation, thereby changing the chemical composition of the product by making a manganese matrix rather than a carbon steel matrix, which is more impact resistant.”

The new impact resistant liner plates have a hardness of between 56 and 58 Rockwell C. Maine observes that normal chromium carbide plates have a measurement of 60 plus Rockwell C hardness. “Where you are gaining in impact resistance with the new liner plates, you are losing on the sliding abrasion or hardness of the plate.”

The new liner plates are still undergoing impact tests in order to determine the limits and capabilities of the product.Maine points out that Rio-Carb will offer the same support to the new liner plates as it does for its other product ranges. “The after sales support will be the same for all our products. There is very little variation between the new liner plates and our older products, the newer products are simply more impact resistant. Therefore they fit perfectly into our current product range.We provide full support on the liner plates and are readily available and open for repairs due to wear and tear, as long as there has been no negligence.”

Maine highlights that the new liner plates allow Rio-Carb to expand its reach in the market. “There was a gap in our product range which has now been filled by the new impact resistant liners. By filling this gap, we were also addressing a demand in industry for higher impact resistant products. Our impact resistant liners can now be used in areas where in the past we were restricted due to the impact factor. We are no longer restricted in those areas. We were specialised in the sliding abrasion market and now we are opening up into the impact abrasion market,” he concludes.

Ends

Notes to the Editor

There are numerous photographs specific to this press release. Please visit http://media.ngage.co.za and click the Rio-Carb link.

About Rio-Carb

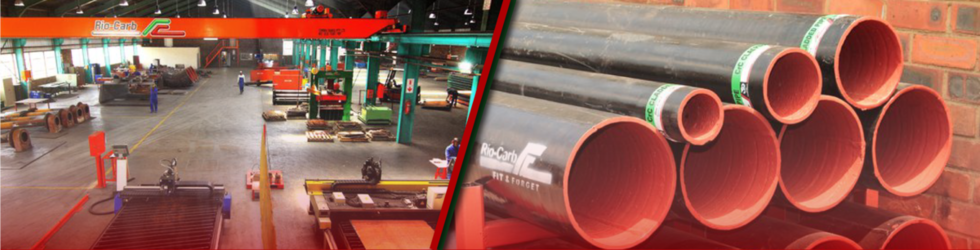

Rio-Carb manufactures wear-resistant Chromium Carbide clad liner plates for heavy materials handling applications in the mining and allied resources industries. The company was initially motivated by Martin Maine, who had experience in the welding and manufacturing industries. He was importing the current product from Australia, and saw the opportunity to establish local manufacture in 1982, when Rio-Tinto had ambitions to establish manufacturing companies allied to mining, and therefore, financed and capitalised the new Rio-Carb for local manufacture. After being in the Rio-Tinto (SA) stable for 16 years, there was a management buy-out by the existing and current share-holders.

Rio-Carb Contact

Martin Maine

Rio-Carb director

Phone: (011) 908 1014

Fax: (011) 908 4139

Email: info [at] riocarb [dot] co [dot] za

Media Contact

Bridgette Macheke

NGAGE Public Relations

Phone: (011) 867-7763

Fax: 086 512 3352

Cell: 083 260 8214

Email: renay [at] ngage [dot] co [dot] za

Web: www.ngage.co.za

Browse the Ngage Media Zone for more client press releases and photographs at http://media.ngage.co.za