Rio-Carb appoints Sias Suurd as General Manager

His extensive experience in the Namibian mining industry includes a stint as Support Equipment Engineering Manager at Husab’s Swakop Uranium Mine, near Swakopmund in the Erongo region in western-central Namibia, the second-largest uranium mine in the world.

In Mpumalanga in South Africa, Suurd worked as Maintenance Engineer at BHP Billiton’s Wolvekrans and Klipspruit collieries. He holds a Bachelor of Mechanical Engineering and Honours in Design Engineering from the University of Pretoria, and a Master’s in Business Administration from the University of Stellenbosch.

Suurd’s extensive technical and business expertise will stand him in good stead to develop Rio-Carb’s market reach even further. Director and founder Martin Maine comments that Suurd has a broad mandate to capitalise on growth opportunities in Namibia and Southern Africa in general.

“Rio-Carb is a great company, and there are significant opportunities to expand the business even further. The main driver here is to promote complete wear solutions focused on clients’ specific needs and specifications, based on chromium carbide as providing the lowest total cost of ownership,” Suurd concludes.

Ends

Notes to the Editor

To download hi-res images for this release, please http://media.ngage.co.za and click the Rio-Carb link to view the company’s press office.

About Rio-Carb

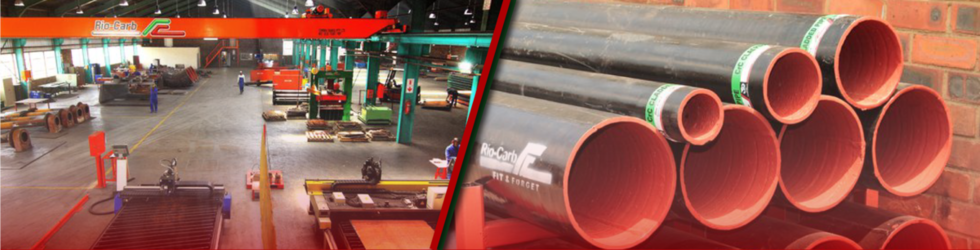

Rio-Carb manufactures wear-resistant Chromium Carbide (CrC) clad liner plates for heavy materials-handling applications in the mining and allied resources industries. With more than 30 years’ experience, its long-life CrC liners have eight to ten times the wear life of industry-standard 400 and 500 BHN steel materials, which reduces operational costs dramatically due to less downtime and change-outs. Rio-Carb has a deep-rooted history in mining, and is able to respond swiftly to customers’ needs in providing cost-effective solutions.

Media Contact

Mmule Ncongwane

NGAGE Public Relations

Phone: (011) 867-7763

Fax: 086 512 3352

Cell: 083 661 8751

Email: mmule [at] ngage [dot] co [dot] za

Web: www.ngage.co.za

Browse the NGAGE Media Zone for more client press releases and photographs at media.ngage.co.za

His extensive experience in the Namibian mining industry includes a stint as Support Equipment Engineering Manager at Husab’s Swakop Uranium Mine, near Swakopmund in the Erongo region in western-central Namibia, the second-largest uranium mine in the world.

In Mpumalanga in South Africa, Suurd worked as Maintenance Engineer at BHP Billiton’s Wolvekrans and Klipspruit collieries. He holds a Bachelor of Mechanical Engineering and Honours in Design Engineering from the University of Pretoria, and a Master’s in Business Administration from the University of Stellenbosch.

Suurd’s extensive technical and business expertise will stand him in good stead to develop Rio-Carb’s market reach even further. Director and founder Martin Maine comments that Suurd has a broad mandate to capitalise on growth opportunities in Namibia and Southern Africa in general.

“Rio-Carb is a great company, and there are significant opportunities to expand the business even further. The main driver here is to promote complete wear solutions focused on clients’ specific needs and specifications, based on chromium carbide as providing the lowest total cost of ownership,” Suurd concludes.

Ends

Notes to the Editor

To download hi-res images for this release, please http://media.ngage.co.za and click the Rio-Carb link to view the company’s press office.

About Rio-Carb

Rio-Carb manufactures wear-resistant Chromium Carbide (CrC) clad liner plates for heavy materials-handling applications in the mining and allied resources industries. With more than 30 years’ experience, its long-life CrC liners have eight to ten times the wear life of industry-standard 400 and 500 BHN steel materials, which reduces operational costs dramatically due to less downtime and change-outs. Rio-Carb has a deep-rooted history in mining, and is able to respond swiftly to customers’ needs in providing cost-effective solutions.

Media Contact

Mmule Ncongwane

NGAGE Public Relations

Phone: (011) 867-7763

Fax: 086 512 3352

Cell: 083 661 8751

Email: mmule [at] ngage [dot] co [dot] za

Web: www.ngage.co.za

Browse the NGAGE Media Zone for more client press releases and photographs at media.ngage.co.za