Rio-Carb applies benefits of CrC to its pipe range

| Rio-Carb applies benefits of CrC to its pipe range_approved | 28 KB | Download | |

| The CrC pipe range from Rio-Carb is ideal for abrasive materials such as slurries. It can withstand heat of up to 600°C | 1.96 MB | Download | |

| The pipes are available in 3 m lengths, in bends, T-shapes and straight pieces. | 5.55 MB | Download | |

| The Plasma pipe cutting machine | 659.58 KB | Download |

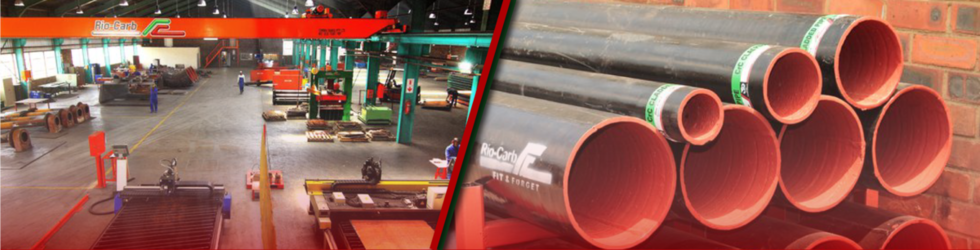

The bore of these pipes is cladded with 4 mm to 6 mm CrC, in an extremely smooth and even layer for good flow results. “We have opted for CrC in our pipe range due to the fact that it is more resistant than ceramics, and also longer-lasting than rubber,” Rio-Carb Product Development Manager Luis Garcia explains.

The pipes are available in 3 m lengths, in bends, T-shapes and straight pieces. They can be supplied loose, or with fitted flanges according to customer requirements. The CrC cannot chip off, in addition to being easily weldable on the outside. The CrC pipe range from Rio-Carb is ideal for abrasive materials such as slurries. It can withstand heat of up to 600°C, and can be rolled, studded, holed and fabricated.

Managing Director Colin Maine points out that the CrC pipe range is an example of the ongoing product development that exemplifies Rio-Carb. “What keeps us ahead of the competition is our emphasis on constant development, in addition to our quality and service. All of our procedures are in accordance with international American Welding Society (AWS) standards.”

The OEM has just invested in a new CRM system, as well as achieving ISO 9001 accreditation, all as it celebrates its 35th anniversary this year. “Our extensive experience in wear linings means we can often detect a problem before the engineers can,” Garcia adds. Rio-Carb prides itself on being proactive in assisting its customers to develop ideal solutions for specific applications or industry-related problems.

“We sit and engage with our customers in order to meet their needs, often at the drawing-office level. Apart from CrC being such a unique product, its benefits are dependent on efficient design and welding, taking into account factors such as low-slip angles, long life, and minimum downtime,” Garcia concludes.

Ends

Notes to the Editor

To download hi-res images for this release, please http://media.ngage.co.za and click the Rio-Carb link to view the company’s press office.

About Rio-Carb

Rio-Carb manufactures wear-resistant Chromium Carbide (CrC) clad liner plates for heavy materials-handling applications in the mining and allied resources industries. With more than 30 years of experience, the company’s long-life CrC liners have 8 to 10 times the wear life of industry-standard 400 and 500 BHN steel materials, which dramatically reduces operational costs as a result of less downtime and change-outs. Rio-Carb has a deep-rooted history in mining, and is able to swiftly respond to customers' needs in providing cost-effective solutions.

Rio-Carb Contact

Martin Maine

Director

Phone: (011) 908 1014

Fax: (011) 908 4139

Email: info [at] riocarb [dot] co [dot] za

Web: www.riocarb.co.za

Media Contact

Renay Tandy

NGAGE Public Relations

Phone: (011) 867 7763

Fax: 086 512 3352

Cell: 082 562 5088

Email: renay [at] ngage [dot] co [dot] za

Web: www.ngage.co.za

Browse the NGAGE Media Zone for more client press releases and photographs at media.ngage.co.za