Rio-Carb achieves ISO 9001 Quality Assurance accreditation

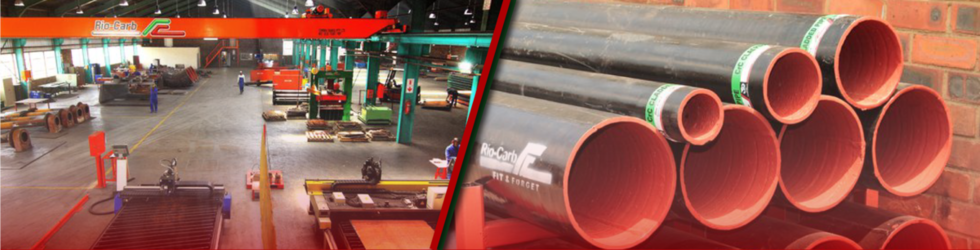

A leading manufacturer of wear-resistant Chromium Carbide (CrC) clad liner plates for heavy materials-handling applications in the mining and allied resources industries, Rio-Carb embarked on the accreditation process in order to boost its manufacturing processes and to assure customers of the quality of its products.

“Our products are highly specialised and not just off-the-shelf. We deal with many major customers in the mining industry, where such accreditation is mandatory. We are very proud of having achieved this quality assurance,” Director Jenny Maine comments, who oversaw the ISO implementation at Rio-Carb.

Quality-assurance processes adopted at the manufacturer include holding weekly Toolbox Meetings, making a suggestion box available for employees to put forward their ideas for any improvements, and to conduct regular customer surveys in order to be able to benchmark product quality and service offering.

“We are committed to achieving total customer satisfaction through constant improvement in our business processes. Therefore attaining ISO 9001 was an important step in achieving this,” Maine comments.

The aim is to manufacture long-life wear liners that conform to the highest possible quality standards, from the stainless steel studs, to our Rapid Removal system, tight cutting tolerances and ease of movement, coupled with Plasma-Etched part numbers for easy identification and replacement.

Maine reveals that the next stage is for Rio-Carb to implement the ISO 14001:2015 environmental management system, which will benchmark its manufacturing processes even further. “An important criterion for ISO 14001 is resource conservation. Our long-life wear solutions play a critical role in boosting materials-handling efficiency and cost-effectiveness,” she concludes.

Ends

Notes to the Editor

To download hi-res images for this release, please http://media.ngage.co.za and click the Rio-Carb link to view the company’s press office.

About Rio-Carb

Rio-Carb manufactures wear-resistant Chromium Carbide (CrC) clad liner plates for heavy materials-handling applications in the mining and allied resources industries. With more than 30 years of experience, the company’s long-life CrC liners have 8 to 10 times the wear life of industry-standard 400 and 500 BHN steel materials, which dramatically reduces operational costs as a result of less downtime and change-outs. Rio-Carb has a deep-rooted history in mining, and is able to swiftly respond to customers' needs in providing cost-effective solutions.

Rio-Carb Contact

Martin Maine

Director

Phone: (011) 908 1014

Fax: (011) 908 4139

Email: info [at] riocarb [dot] co [dot] za

Web: www.riocarb.co.za

Media Contact

Renay Tandy

NGAGE Public Relations

Phone: (011) 867 7763

Fax: 086 512 3352

Cell: 082 562 5088

Email: renay [at] ngage [dot] co [dot] za

Web: www.ngage.co.za

Browse the NGAGE Media Zone for more client press releases and photographs at media.ngage.co.za