R1m investment in local production improves efficiency and creates jobs

| R1m investment in local production improves efficiency and creates jobs | 15.58 KB | Download | |

| Aury Africa's managining director Mark Houchin | 4.24 MB | Download | |

| Aury Africa has invested R1-million in two new looms being used in the local manufacture of woven wire screens | 3.7 MB | Download | |

| Aury Africa began locally manufacturing all woven wire screens in August 2014 | 4.23 MB | Download |

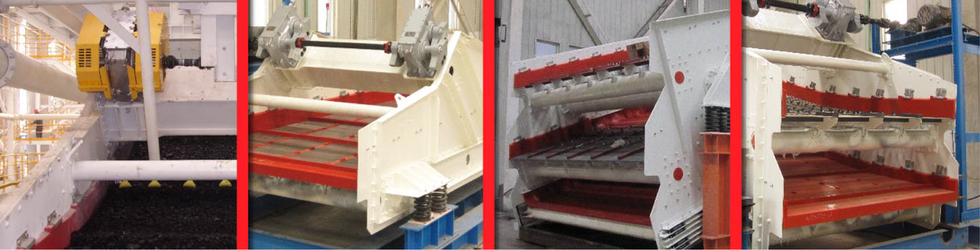

Following a R1-million investment in two new looms, which were commissioned in July 2014 to manufacture woven wire screens, Aury Africa is meeting its production targets efficiently. Managing director Mark Houchin says: “We are extremely satisfied with the progression that we have made in terms of local production, and are on track towards meeting our target of 1 000 screens per month.”

The 5 000 m2 facility Jet Park, Boksburg, features a large loom for weaving wires larger than 5 mm, and a small loom for weaving wires below 5 mm. The large loom is capable of manufacturing screens up to 3 m wide and 20 m long. The small loom has the capacity to manufacture screens up to 2 m in width and 10 m in length. All screens are cut to size after production.

Both looms run on an around-the-clock basis in order to meet production targets and growing demand from clients operating predominantly in the plants and quarries sectors. Houchin adds: “The most popular aperture sizes are generally between 3,15 mm and 12,5 mm. We are able to manufacture on a larger or smaller basis, depending on the specifications of each customer.”

Aury Africa has also created six new full-time operational positions by localising production. As a result, the company’s staff complement has risen from 36 to 42 employees, as a permanent night shift has been established in order to keep up with rising demand from across Africa.

According to Houchin, local production has dramatically improved turnaround times too. “Importing the woven wire screens from our China-based sister company, Aury Tianjin typically resulted in a three month turnaround time for clients. Since we started local production, this lead time has been reduced to around two weeks, which is a major value-add for our customer base.”

Houchin states that local manufacture has also minimised the need for excessive stockholding. “In the past, we attempted to negate the effects of prolonged turnaround times by holding large amounts of stock. The challenge here was that some items sold quicker than others, and millions of rands worth of screens would lie on the floor. This was not a cost-effective business model.”

Given the initial success of the local manufacturing facility, Houchin is confident of the future outlook. “Our success has exceeded all expectations, and looks set continue in the future. Bearing this in mind, I am confident of gaining measurable market share in regions that include our established base in South Africa, as well as developing Sub-Saharan African markets, and even as far afield as Sri Lanka,” he concludes.

Ends

Notes to the Editor

There are numerous photographs specific to this press release. Please visit http://media.ngage.co.za and click the Aury Africa link.

About Aury Africa

Aury Africa's goal is to provide the best innovative screening and vibrating equipment solutions and services to the African mining market. Aury Africa takes advantage of the economies of scale provided by large-scale Chinese production from its ISO-9001 accredited sister company, Aury (Tianjin), with the aid and assistance of technical know-how developed in Australia and South Africa.

Aury also has a sound research and design capability, backed up by the technical expertise of a number of engineers who boast extensive experience in vibration technology within the mining sector. Aury design engineers think outside the box to provide traditional vibrating technology with leading edge thinking and design techniques to produce innovative capital equipment that is superior to anything found within the market today.

Aury Africa Contact Details

Matthew van Buuren

Sales and Marketing Administrator

Tel: (011) 026 6642

Email: matt [at] auryafrica [dot] co [dot] za

Web: www.auryafrica.co.za

Media Contact

Renay Tandy

NGAGE Public Relations

Phone: (011) 867 7763

Fax: 086 512 3352

Cell: 082 562 5088

Email: renay [at] ngage [dot] co [dot] za

Web: www.ngage.co.za

Browse the Ngage Media Zone for more client press releases and photographs at http://media.ngage.co.za