New wear survey and wear mapping service minimises downtime costs

The service was officially launched in August 2015, and is a proactive solution to the costly and time-consuming effects that unforeseen wear can have on all liners and pipes carrying abrasive materials. Rio-Carb product development manager Luis Garcia reveals that the company is able to produce a wear map, which reveals the greatest wear areas on materials handling equipment, by using advanced ultrasonic equipment that is operated by staff that are qualified in chute draughting.

“This can result in huge savings for customers, as areas of less wear may not require replacement. The thickness measurements are carried out to the nearest 0.1 mm, and the areas are zoned by permanent marking, thereby ensuring that subsequent replacement checks can be reliably predicted. We are also able to estimate when and where our Chromium Carbide (CrC) liners should be installed by identifying the sharp-end of the wear system,” he explains.

Garcia says that this service is also of great importance when planning shut-downs for maintenance. “A costly industry trend is to wait for a hole to appear in the chute before replacing the entire liner. This only leads to increased downtime and more liner material being used. A monthly calculation of wear loss on each wear plate enables us to calculate the most suitable times for replacement.”

The wear survey and wear mapping service is available to operations in the mining and allied resources industries. Garcia notes that it has been trialled at a South African coal mining operation since July 2015, with positive results. “The encouraging feedback prompted us to go live with this offering, which also enables us to improve our turnaround times and efficiency, by better preparing for future supply and demand, based on strategic calculations undertaken on site,” he concludes.

To find out more about the wear survey and wear mapping service offering, contact Rio-Carb on (011) 908 1014, email info [at] riocarb [dot] co [dot] za or visit www.riocarb.co.za

Ends

Notes to the Editor

To download hi-res images for this release, please visit http://media.ngage.co.za and click the Rio-Carb link to view the company’s press office.

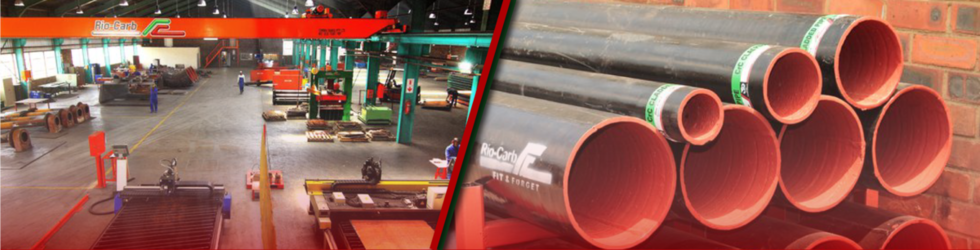

About Rio-Carb

Rio-Carb manufactures wear-resistant Chromium Carbide (CrC) clad liner plates for heavy materials-handling applications in the mining and allied resources industries. With more than 30 years of experience, the company’s long-life CrC liners have 8 to 10 times the wear life of industry-standard 400 and 500 BHN steel materials, which dramatically reduces operational costs as a result of less downtime and change-outs. Rio-Carb has a deep-rooted history in mining, and is able to swiftly respond to customers' needs in providing cost-effective solutions.

Rio-Carb Contact

Martin Maine

Rio-Carb Director

Phone: (011) 908 1014

Fax: (011) 908 4139

Email: info [at] riocarb [dot] co [dot] za

Web: www.riocarb.co.za

Media Contact

Jana Klut

NGAGE Public Relations

Phone: (011) 867-7763

Fax: 086 512 3352

Cell: 074 111 4900

Email: jana [at] ngage [dot] co [dot] za

Web: www.ngage.co.za

Browse the NGAGE Media Zone for more client press releases and photographs at http://media.ngage.co.za