New mini vibrating screens to better suit the African market

| New mini vibrating screens to better suit the African market | 15.6 KB | Download | |

| Aury Africa MD Mark Houchin | 3.68 MB | Download | |

| New mini vibrating screens to better suit the African market | 1.1 MB | Download | |

| the company is now able to meet customers’ specific needs with mini vibrating screens. | 1.17 MB | Download | |

| The screens were introduced in early-2015 | 39.17 KB | Download | |

| Vibrating screens play an important role in the mineral extraction process across many industries | 1.15 MB | Download |

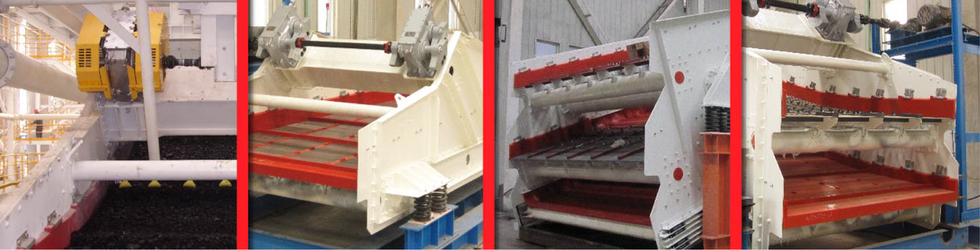

Vibrating screens play an important role in the mineral extraction process across many industries. A large amount of materials are made up of hard, tough rock masses that need to be crushed before the valuable minerals can be released. Vibrating screens are used after the crushing process for numerous applications, such as material classification and dewatering of materials.

Aury Africa MD Mark Houchin explains that the company is now able to meet customers’ specific needs with mini vibrating screens. “Our mini screens are between 1,2 m wide and 2,4 m wide, although smaller screens can be provided according to client specifications,” he explains.

According to Houchin, a study revealed that Aury screens between 1,2 m and 2,4 m wide were slightly over-designed in terms of their heavy-duty capabilities, particularly for the South African coal market. “Screens this size do not require the same heavy-duty characteristics as the larger ones. As a result, Aury Africa requested that its China-based factory manufacture a fit-for-purpose screen to accommodate the duty tolerances for the 1,2 m to 2,4 m wide range only.”

The screens were introduced in early-2015, and can ensure 30 to 40 percent savings over the current screen prices. “This is a major advantage in challenging economic conditions, and is achieved by, amongst other things, weight saving initiatives by reducing the polyurethane coating on the cross beams from 6 mm to 2 mm thick. A 6 mm polyurethane coating is applied to a 2,4 m to 4,9 m wide screen to accommodate considerably larger volumes. This is extra built-in capacity that is simply not required on smaller screens,” states Houchin.

Houchin explains that the Aury Africa mini vibrating screens are made of thinner steel side plates and can be fitted with out of balance motors or exciters for efficient screening. “The mini vibrating screens are extremely robust with a high throughput per screening area,” he continues.

Aury Africa stocks and supplies a complete range of equipment such as vibrating feeders and screens, fine and coarse coal centrifuges, crushers, and conveyor systems. It also stocks a range of consumable products that include; polyurethane and rubber panels, cyclones, woven wire screens, weld mesh, wedge wire products, pipes, pumps, belt scrapers and ceramics.

Even though the market has been sluggish for some time, Houchin says that the demand for the company's range of products continues to remain stable within the local coal mining and mineral processing industries. “This is mainly because Aury Africa provides consumables to existing equipment, in addition to carrying out equipment servicing, installation and maintenance.”

Ends

Notes to the Editor

To download hi-res images for this release, please visit http:/media.ngage.co.za and click the Aury Africa link to view the company’s press office.

About Aury Africa

Aury Africa's goal is to provide the best innovative screening and vibrating equipment solutions and services to the African mining market. Aury Africa takes advantage of the economies of scale provided by large-scale Chinese production from its ISO-9001 accredited sister company, Aury (Tianjin), with the aid and assistance of technical know-how developed in Australia and South Africa.

Aury also has a sound research and design capability, backed up by the technical expertise of a number of engineers who boast extensive experience in vibration technology within the mining sector. Aury design engineers think outside the box to provide traditional vibrating technology with leading edge thinking and design techniques to produce innovative capital equipment that is superior to anything found within the market today.

Aury Africa Contact Details

Matthew van Buuren

Sales and Marketing Administrator

Tel: (011) 026 6642

Email: matt [at] auryafrica [dot] co [dot] za

Web: www.auryafrica.co.za

Media Contact

Jana Klut

NGAGE Public Relations

Phone: (011) 867 7763

Fax: 086 512 3352

Cell: 074 111 4900

Email: jana [at] ngage [dot] co [dot] za

Web: www.ngage.co.za

Browse the NGAGE Media Zone for more client press releases and photographs at http://media.ngage.co.za