Locally-manufactured woven wire screens extend production hours

| Press release_Locally-manufactured woven wire screens extend production hours_approved | 19.34 KB | Download | |

| Aury Africa woven wire screens | 2.15 MB | Download | |

| The AfriSam Olifantsfontein quarry is a dolomite aggregate operation that produces a wide range of products | 1.82 MB | Download | |

| The dolomite aggregate produced is predominantly consumed by concrete producers, due to the fact that it has cementitious proper | 2.73 MB | Download | |

| The dolomite aggregate produced is predominantly consumed by concrete producers.JPG | 1.89 MB | Download | |

| (RIGHT) Aury Africa regional sales manager Ameen Peters and (LEFT) AfriSam production superintendent Joseph Dlamini | 2.09 MB | Download |

PRESS RELEASE

Locally-manufactured woven wire screens extend production hours

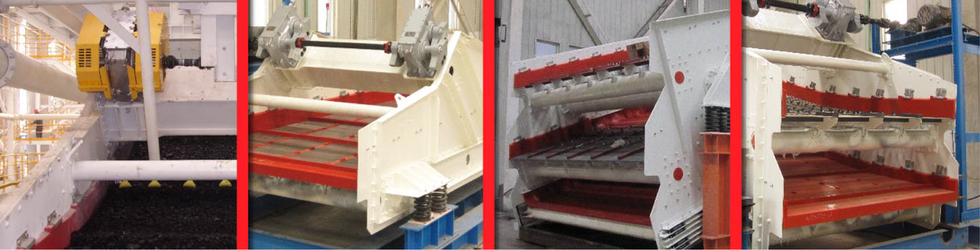

26 May 2016: The AfriSam Olifantsfontein readymix and aggregate quarry in Gauteng has been making use of Aury Africa woven wire screens since 2014. Aury Africa wire screens are more cost-effective and last up to five days longer than competitor products, thereby minimising downtime and ensuring substantial long-term savings.

The AfriSam Olifantsfontein quarry is a dolomite aggregate operation that produces a wide range of products – including sand, ballast, gravel, crushed stones and cement – which range in size from 0.075 micron to 26.5 mm. The dolomite aggregate produced is predominantly consumed by concrete producers, due to the fact that it has cementitious properties.

The quarry recently completed a plant upgrade, which involved the repositioning of the whole primary jaw crusher to increase tonnages. As a result of this capital-intensive investment, AfriSam production superintendent Joseph Dlamini notes that it is essential for the operation to minimise excessive costs on plant consumables.

“The previous supplier’s wire mesh lasted about 800 hours before it needed to be changed. Since switching to the Aury Africa range, changing intervals have significantly improved to 850 hours, which equates to approximately five more days of screening per screen cloth. It takes many hours to change a screen due to weight and dimensions. Since we spend less time removing Aury Africa screens, we can capitalise on our investment, which places us ahead of our competitors,” he says.

According to Dlamini, gone are the days where operations remain blindly loyal to suppliers. “In challenging economic times, it is essential to achieve cost savings without compromising on quality. In-depth Research into reputable suppliers is essential. Opting for Aury Africa as a supplier is already paying dividends – as 50 additional hours from a single screen cloth is a measurable saving.”

With less time and money being spent on changing screens while separating excavated materials, Dlamini adds that the Aury Africa woven wire screen cloths have improved productivity at the Olifantsfontein quarry. “This also enables us to extract, sort and deliver our superior quality aggregates to our customer base in the quickest turnaround times.”

Dlamini believes that Aury Africa’s after-sales service and technical support is unrivalled. “A new screen cloth with new screen opening size, wire diameter, and attachment typically takes around 15 days. In some cases, we may require the screen in considerably shorter timeframes, due to customer demands, and Aury Africa representatives are always happy to accommodate us.”

Aury Africa regional sales manager Ameen Peters reveals that the company recently invested in two looms used in the local manufacture of woven wire screens. “The primary advantage of local production is that the fact that we have dramatically improved turnaround times from around six weeks, to just days after the order is placed. This is a major value-added service that is sure to further consolidate our trusted reputation.”

Peters highlights the fact that Aury Africa also offers after-sales consultation on the most suitable screens for specific applications, and how best to utilise the selected screens. “Our customers enjoy the added peace-of-mind of knowing exactly when their screens need to be replaced, and they can easily work replacements into their budget beforehand,” he concludes.

Ends

Notes to the Editor

To download hi-res images for this release, please visit media.ngage.co.za and click the Aury Africa link to view the company’s press office.

About Aury Africa

Aury Africa's goal is to provide the best innovative screening and vibrating equipment solutions and services to the African mining market. Aury Africa takes advantage of the economies of scale provided by large-scale Chinese production from its ISO-9001 accredited sister company, Aury (Tianjin), with the aid and assistance of technical know-how developed in Australia and South Africa.

Aury also has a sound research and design capability, backed up by the technical expertise of a number of engineers who boast extensive experience in vibration technology within the mining sector. Aury design engineers think outside the box to provide traditional vibrating technology with leading edge thinking and design techniques to produce innovative capital equipment that is superior to anything found within the market today.

Aury Africa Contact Details

Kelly Houchin

Sales Administrator

Tel: (011) 026 6642

Email: kelly [at] auryafrica [dot] co [dot] za

Web: www.auryafrica.co.za

Media Contact

Jana Klut

NGAGE Public Relations

Phone: (011) 867 7763

Fax: 086 512 3352

Cell: 074 111 4900

Email: jana [at] ngage [dot] co [dot] za

Web: www.ngage.co.za

Browse the NGAGE Media Zone for more client press releases and photographs at media.ngage.co.za