Ideal wear solution from truck beds to shovel buckets and dozer blades

| Ideal wear solution from truck beds to shovel buckets and dozer blades_approved | 31 KB | Download | |

| Offloading material by means of tipping is accelerated due to a reduced friction coefficient. | 1.34 MB | Download | |

| CrC overlay plate is an ideal wear solution for dozer blades and even dragline buckets. | 641.12 KB | Download | |

| Rio-Carb has designed liner packages to match the wear pattern on the load body. | 991.88 KB | Download | |

| Rio-Carb General Manager Sias Suurd | 2.46 MB | Download |

The plate features a standard smooth surface with relief cracks, a ductile and workable backplate, a quality-controlled fusion zone, and a hard CrC overlay. It forms the basis of an engineered truck bed liner system that offers significant cost of ownership and return on investment benefits for customers, Rio-Carb General Manager Sias Suurd explains.

Available in a hybrid liner package, the system greatly improves the wear life of truck beds, due to the fact that the plate wears down at a uniform rate, which means it is less maintenance-intensive, as well as increasing productivity dramatically.

Other advantages are that the system has been designed to reduce welding, and can be customised in terms of its overall weight. No micro dead boxes are required at the rear of the truck, with no carry back either. In addition, offloading material by means of tipping is accelerated as a result, due to a reduced friction coefficient.

“Our engineering department is available for consultation for specific customer requirements, while our advanced manufacturing provides a quick turnaround on replacement components,” Suurd adds. In terms of dozer blades and shovel buckets, Rio-Carb manufactures liner packages for a range of models and sizes.

Looking at haul trucks, Suurd highlights that Rio-Carb has designed liner packages with varying thicknesses in order to match the wear pattern on the load body. “The aim is to provide a liner package that wears evenly, thereby providing the longest possible life between liner replacements. The ultimate benefit for customers is a significantly lower total cost of ownership,” he concludes.

Ends

Connect with Rio-Carb on Social Media to receive the company’s latest news

Facebook: https://www.facebook.com/RioCarb/

LinkedIn: https://www.linkedin.com/in/rio-carb-pty-ltd-797496108/

Notes to the Editor

To download hi-res images for this release, please http://media.ngage.co.za and click the Rio-Carb link to view the company’s press office.

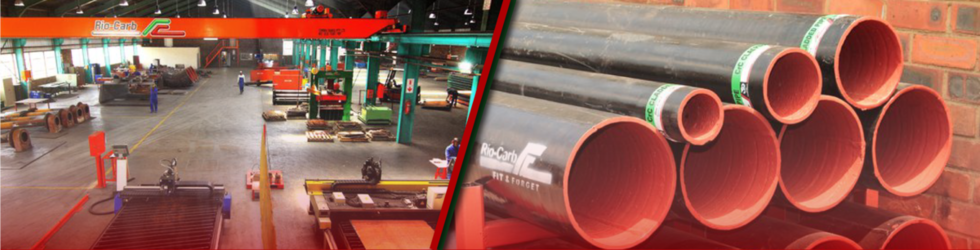

About Rio-Carb

Rio-Carb manufactures wear-resistant Chromium Carbide (CrC) clad liner plates for heavy materials-handling applications in the mining and allied resources industries. With more than 30 years’ experience, the company’s long-life CrC liners have eight to ten times the wear life of industry-standard 400 and 500 BHN steel materials, which reduces operational costs dramatically due to less downtime and change-outs. Rio-Carb has a deep-rooted history in mining, and is able to respond to customers’ needs swiftly in providing cost-effective solutions.

Rio-Carb Contact

Jabu Mlambo

Sales & Marketing Administrator

Phone: (011) 011 6111

Fax: (011) 908 4139

Email: jabu [at] riocarb [dot] co [dot] za

Web: www.riocarb.com

Media Contact

Nomvelo Buthelezi

NGAGE Public Relations

Phone: (011) 867-7763

Fax: 086 512 3352

Cell: 083 408 8911

Email: nomvelo [at] ngage [dot] co [dot] za

Web: www.ngage.co.za

Browse the NGAGE Media Zone for more client press releases and photographs at media.ngage.co.za