Hard-facing welding wire adds value in sliding wear applications

PRESS RELEASE

Hard-facing welding wire adds value in sliding wear applications

05 August, 2014: As part of its continued plans for expansion, top liner plate expert Rio-Carb will be launching a new range of Chromium Carbide (CrC) hard-facing alloyed welding wire that is fully compatible with the company’s flagship range of CrC wear liners.

The Rio-Carb range of CrC hard-facing welding wire, officially launched in South Africa in July 2014, is ideally-suited for use in the mining, power generation, earthmoving, cement and all other industries where abrasion from sliding wear occurs.

Thanks to Rio-CarbMaxCS technology, the wire boasts an optimum hardness of 60 to 62 Rockwell C, well above the industry standard of 58 Rockwell C, and fully exploits the wonderful wear resistant properties of Chromium Carbide – an alloy that Rio-Carb has successfully exploited and developed for some 32 years.

Rio-Carb director Colin Maine explains: “The hard-facing welding wire is 26 percent Chromiumand four to five percent Carbon, and is highly proficient in enhancing intense wear areas where CrC liners are used, due to the fact that the two products are entirely compatible. Another major advantage of the wire is its high deposition rate, and that it requires no shielding gas.”

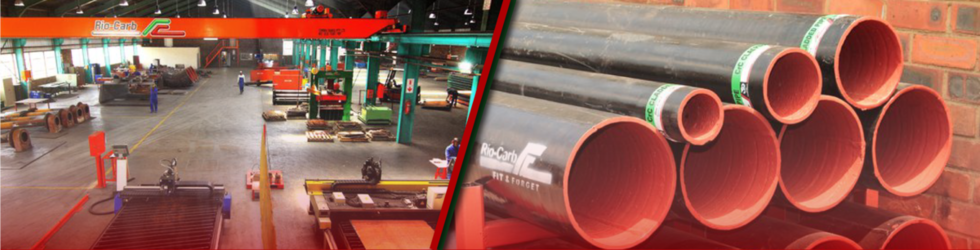

Maine points out that the new hard-facing welding wire conforms to internationally-recognised American Welding Society (AWS) standards and E FeCrA1 specifications, and offers substantial cost savings and improved turnaround times for the local market, thanks to Rio-Carb’s new 3 000 m2 state-of-the-art facility in Alrode, Johannesburg.

Maine indicates that the hard-facing welding wire, which comes in a standard 2,8mm diameter and is supplied in 25kg sealed coils, has received overwhelmingly positive feedback from clients that have tested it on a trial basis.

“High-profile companies operating in the local earthmoving, cement, materials handling and glass manufacturing sectors have all expressed their satisfaction with the product, which is backed up by comprehensive after-sales service and technical support. Bearing this in mind, I am confident of gaining market share and experiencing continued growth in the foreseeable future,” he concludes.

Ends

Notes to the Editor

There are numerous photographs specific to this press release. Please visit http://media.ngage.co.za and click the Rio-Carb link.

About Rio-Carb

Rio-Carb manufactures wear-resistant Chromium Carbide clad liner plates for heavy materials handling applications in the mining and allied resources industries. The company was initially motivated by Martin Maine, who had experience in the welding and manufacturing industries. He was importing the current product from Australia, and saw the opportunity to establish local manufacture in 1982, when Rio-Tinto had ambitions to establish manufacturing companies allied to mining, and therefore, financed and capitalised the new Rio-Carb for local manufacture. After being in the Rio-Tinto (SA) stable for 16 years, there was a management buy-out by the existing and current share-holders.

Rio-Carb Contact

Martin Maine

Rio-Carb director

Phone: (011) 908 1014

Fax: (011) 908 4139

Email: info [at] riocarb [dot] co [dot] za

Media Contact

Bridgette Macheke

NGAGE Public Relations

Phone: (011) 867-7763

Fax: 086 512 3352

Cell: 083 260 8214

Email: renay [at] ngage [dot] co [dot] za

Web: www.ngage.co.za

Browse the Ngage Media Zone for more client press releases and photographs at http://media.ngage.co.za