CrC-lined chutes improve productivity and efficiency at power plant

| Press release_CrC-lined chutes improve productivity and efficiency at power plant_Approved | 15.94 KB | Download | |

| Rio-Carb Director Martin Maine | 2.08 MB | Download | |

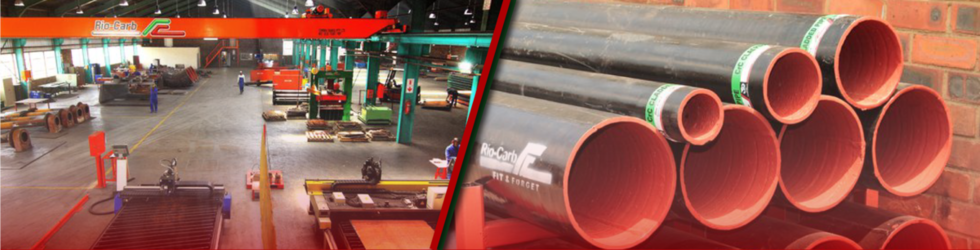

| R-C 700 pipes | 1.63 MB | Download | |

| Rio-Carb has ensured a saving of more than R100 000 for a power plant in Secunda, after successfully refurbishing three chutes | 2.4 MB | Download |

PRESS RELEASE

CrC-lined chutes improve productivity and efficiency at power plant

20 January, 2016: Chromium Carbide (CrC) liner plate expert Rio-Carb has ensured a saving of more than R100 000 for a power plant in Secunda, after successfully refurbishing three chutes and fitting them with CrC liner plates.

Rio-Carb director Martin Maine explains that the project, which has been ongoing for five years, was extended due to the impressive performance of the R-C 700 liner plates. “Rio-Carb had already installed liner plates, in the three 60 m2 chutes at the plant. We have also been tasked with supplying the utility with R-C 700 pipes, which outlast the current pipes ten-fold.”

The chutes at the plant were previously fitted with ceramic 2 m bolted liners, which were not suitable for the project’s specific wear rate, thereby resulting in erosion and blockages in the chutes. Rio-Carb replaced the ceramic liners with 500 mm x 500 mm R-C 700 liner plates, which are manufactured to the chute specifications. The refurbishment included; sandblasting, welding and re-fitting. Rio-Carb repaired the holes in the chutes, and then standardised the liner sizes to an easy-to-handle weight.

According to Maine, the average chute lasts for at least three years. “Standard refurbishments cost at least R2-million every three months, while with Rio-Carb’s R-C 700, it is around R1-million every three years. Using MaxCS technology, Rio-Carb is able to take the properties of CrC and cast it via a welding process onto a mild steel backing plate, which gives it an optimum hardness of 58 RC, and additional flexibility for moulding and shaping.”

The liner plates are also marked with a unique identification number and recorded in the company’s database. This enables the customer to get the correct liner plate sizes immediately, and eliminates the need for onsite measurements. “Rio-Carb also provides an obligation-free wear survey consultation by sending a wear specialist onsite to measure the thickness of the liner plate using ultra-sonic technology to determine when they need to be replaced. This not only saves costs, it helps to accurately prepare for downtime too,” Maine concludes.

Ends

Notes to the Editor

To download hi-res images for this release, please http://media.ngage.co.za and click the Rio-Carb link to view the company’s press office.

About Rio-Carb

Rio-Carb manufactures wear-resistant Chromium Carbide (CrC) clad liner plates for heavy materials-handling applications in the mining and allied resources industries. With more than 30 years of experience, the company’s long-life CrC liners have 8 to 10 times the wear life of industry-standard 400 and 500 BHN steel materials, which dramatically reduces operational costs as a result of less downtime and change-outs. Rio-Carb has a deep-rooted history in mining, and is able to swiftly respond to customers' needs in providing cost-effective solutions.

Rio-Carb Contact

Martin Maine

Rio-Carb Director

Phone: (011) 908 1014

Fax: (011) 908 4139

Email: info [at] riocarb [dot] co [dot] za

Web: www.riocarb.co.za

Media Contact

Jana Klut

NGAGE Public Relations

Phone: (011) 867-7763

Fax: 086 512 3352

Cell: 074 111 4900

Email: jana [at] ngage [dot] co [dot] za

Web: www.ngage.co.za

Browse the NGAGE Media Zone for more client press releases and photographs at http://media.ngage.co.za