CNC plasma cutting machine ensures precision-cut CrC-lined pipes

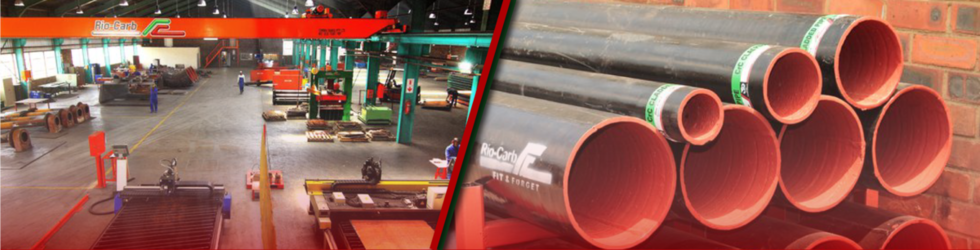

The CNC plasma cutting machine was officially commissioned in May 2015, in response to demands from local industrial operations, says Rio-Carb Product Development Manager Luis Garcia. “We are now in a position to speedily design, spool and flange wear-resistant installations on a turnkey basis. The solution has already been well-received by the diamond mining and petrochemical industries.”

The CNC plasma cutting process is considerably more accurate than flame cutting, thereby ensuring that the angles of the pipes are fully-maintained. “Due to the extreme accuracy of this programmed CNC plasma process, the cutting gap is kept to a maximum of 1 mm. This ensures that the inside hardfaced surface is therefore not exposed to ‘soft’ open gaps,” Garcia continues.

In addition to accurately maintaining the desired angles, the plasma cutting process also eliminates the need for internal welding, which ensures uninterrupted flow of materials. Garcia adds: “The CrC-lined pipes are welded to a smooth fully penetrated finish on the inside, which prevents internal blockages that could interrupt material flow, and even cause severe plant damage in the event of a burst pipe.”

The CNC plasma cutting machine caters to pipe diameters from 100 mm to 400 mm. According to Rio-Carb director Martin Maine, CrC is particularly suitable for mining and process applications where ceramic-lined pipelines have broken down due to flaking and peeling of the ceramic blocks. “Our CrC pipes are also heat, vibration and bending stress resistant, making them ideal for other applications such as ash handling, slurry and dust extraction,” he points out.

The Rio-Carb CrC-lined pipes have an outer shell of mild steel which is easily welded and flanged into any configuration. The wall thickness is typically 10 mm (4 mm CrC on 6 mm mild steel). Maine highlights the fact that all Rio-Carb CrC-lined pipes can be manufactured according to exact specifications. “The client can send us a drawing, and we will build it according to that specification, before delivering the final product onsite for the client to install,” he continues.

For existing installations, Maine reveals that Rio-Carb boasts the ability to reverse engineer onsite pipes and replace them with CrC-lined ones. “Over time, ceramic-lined pipes become brittle, and have to be replaced regularly due to damage. CrC-lined pipes are more robust, which ensures a prolonged lifespan and fewer maintenance and repair intervals, which improves productivity. Bearing this in mind, I am confident of obtaining measurable future growth,” he concludes.

Ends

Notes to the Editor

To download hi-res images for this release, please visit http://media.ngage.co.za and click the Rio-Carb link to view the company’s press office.

About Rio-Carb

Rio-Carb manufactures wear-resistant Chromium Carbide (CrC) clad liner plates for heavy materials-handling applications in the mining and allied resources industries. With more than 30 years of experience, the company’s long-life CrC liners have 8 to 10 times the wear life of industry-standard 400 and 500 BHN steel materials, which dramatically reduces operational costs as a result of less downtime and change-outs. Rio-Carb has a deep-rooted history in mining, and is able to swiftly respond to customers' needs in providing cost-effective solutions.

Rio-Carb Contact

Martin Maine

Rio-Carb Director

Phone: (011) 908 1014

Fax: (011) 908 4139

Email: info [at] riocarb [dot] co [dot] za

Web: www.riocarb.co.za

Media Contact

Jana Klut

NGAGE Public Relations

Phone: (011) 867-7763

Fax: 086 512 3352

Cell: 074 111 4900

Email: jana [at] ngage [dot] co [dot] za

Web: www.ngage.co.za

Browse the NGAGE Media Zone for more client press releases and photographs at http://media.ngage.co.za